I have learned that scaled models are used in just about every industry that involves a design process: amusement park rides, products, and architecture just to name a few.

I began making models out of everyday craft supplies for fun, but I now make models professionally to visualize my concepts.

Foam-Core Models

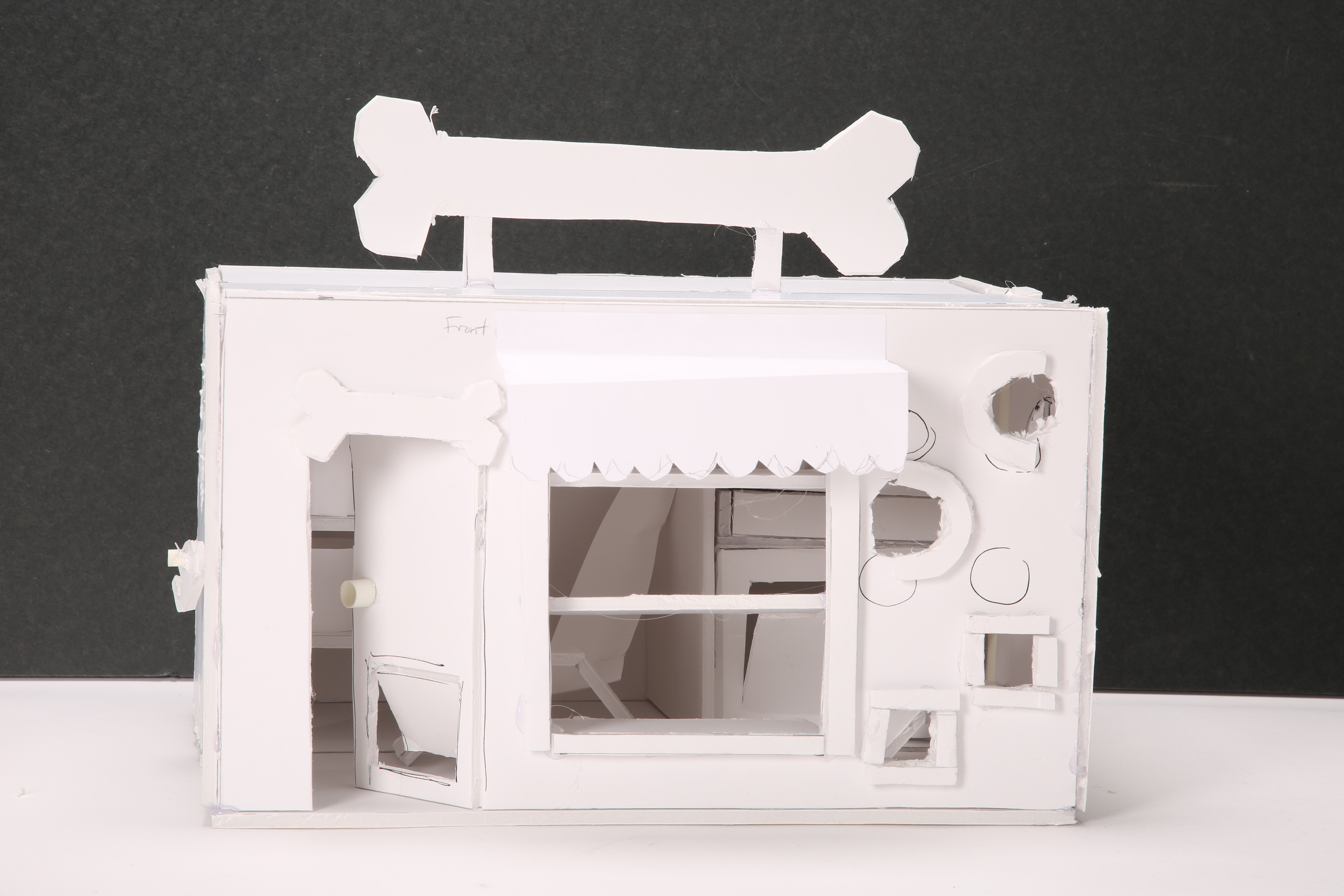

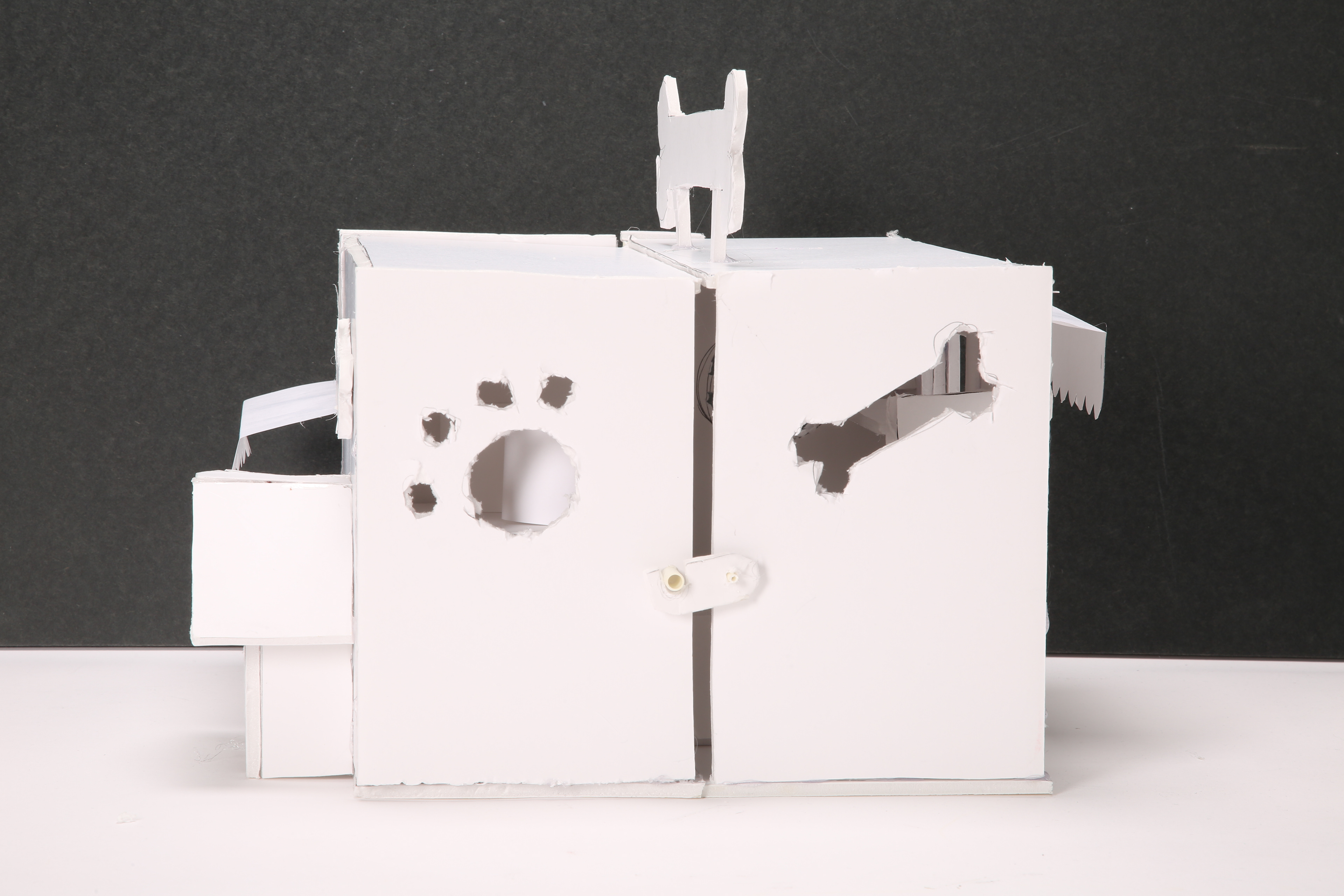

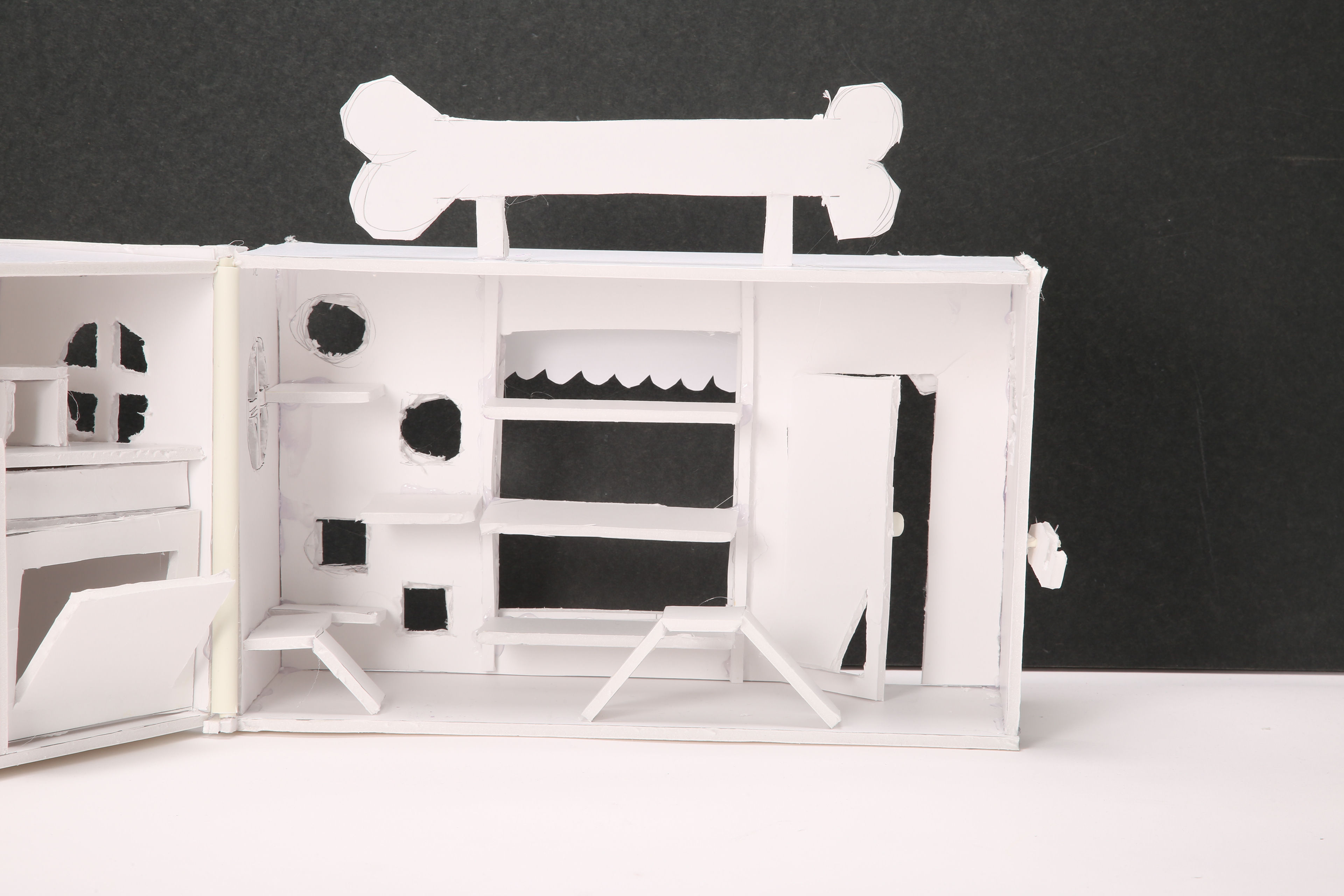

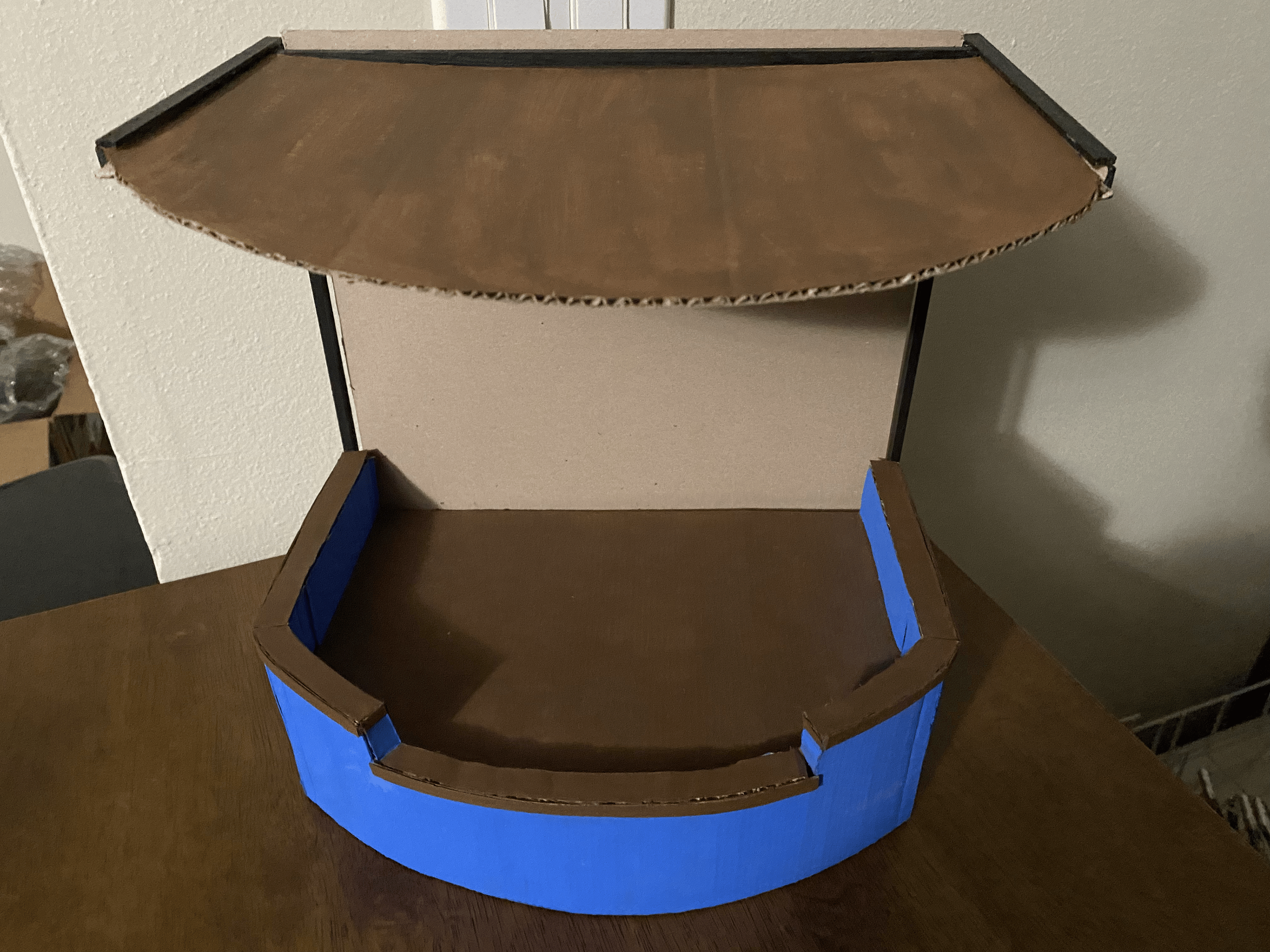

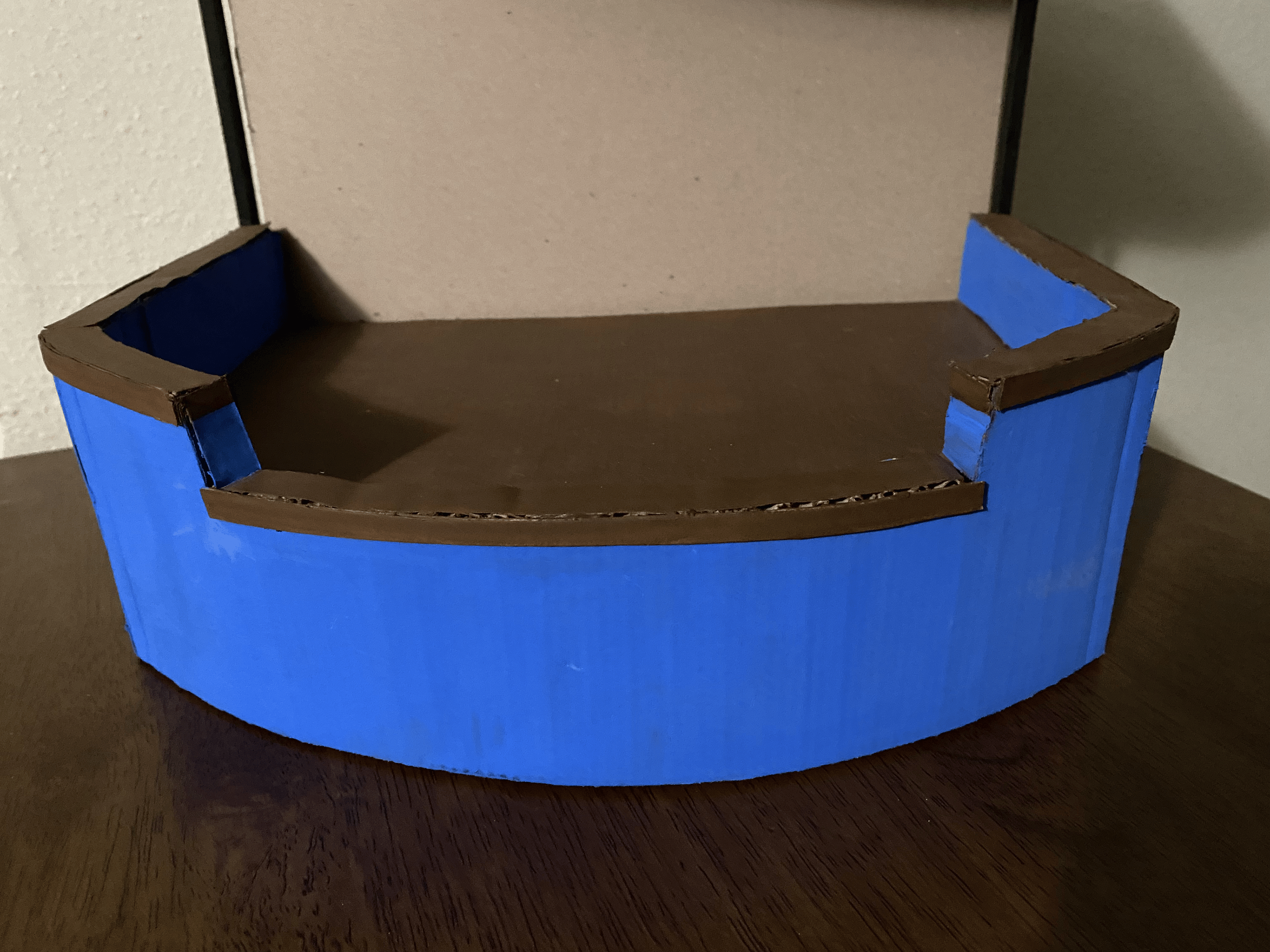

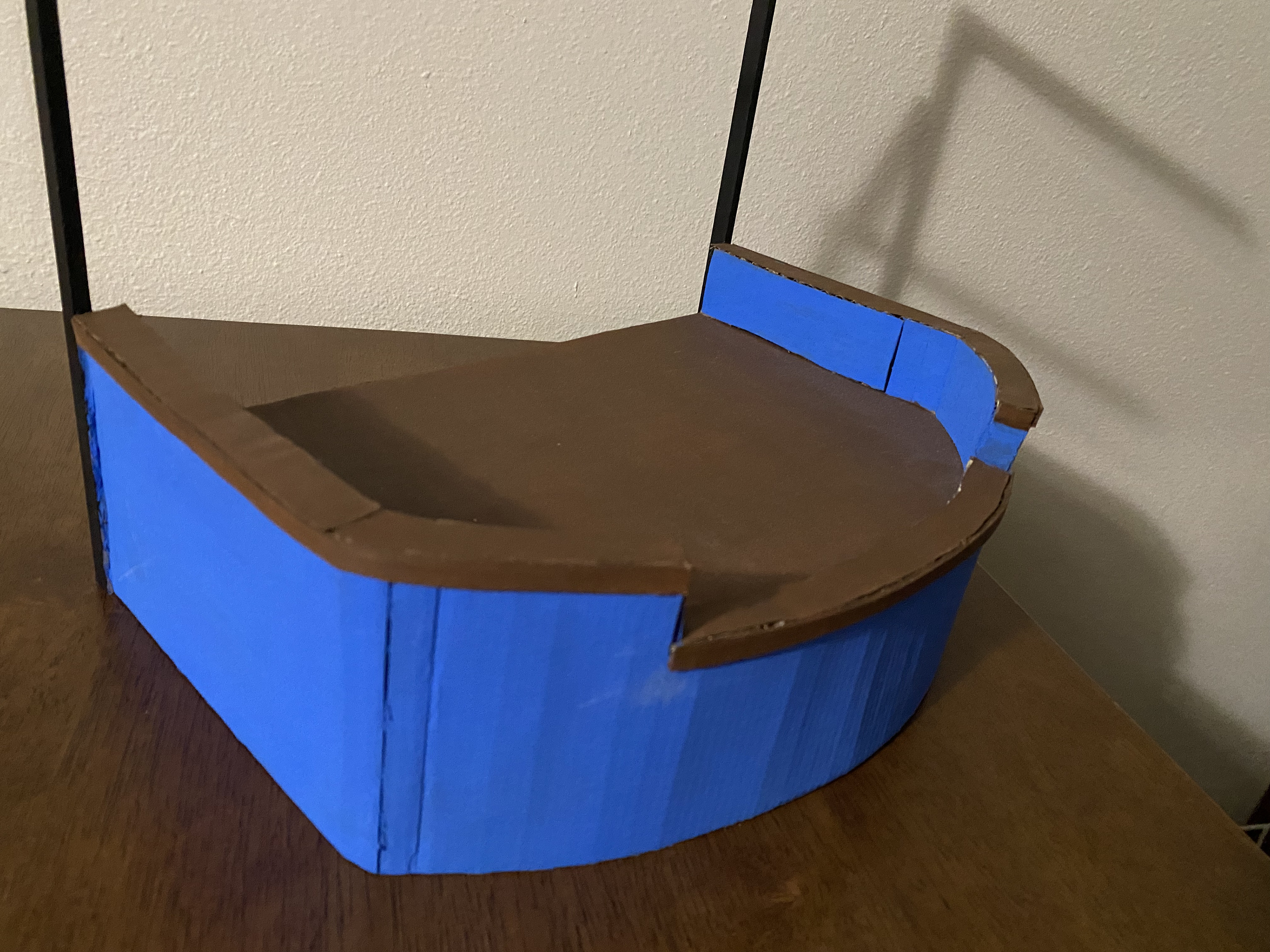

Mattel's Toy Clash 2023 Competition Winner "Puppy Pantry" Foam-core Model

Mattel holds an annual "Toy Clash" competition in which teams of artists, engineers, and marketers are assigned a random theme and play-pattern that they have to come up with an all new toy concept for in under two days.

This is the model I built in 3hrs, the day of the pitch (hence why it's a bit rough).

It was a real test of teamwork, ingenuity, and time management. Utilizing every team member's specialty to design a new toy, and then present a cohesive 20 minute pitch to a panel of judges and the competing teams (not to mention, anyone in the company who wants to attend as well).

I pitched this model in a classic television advert style, similar to that of a "Shark Tank" pitch. Ultimately, our team not only met the criteria of the challenge, but did so in a winning way!

Scaled Animatronic Mechanism Models

These models were my introduction into understanding animatronic mechanisms. I learned all there is to know about how linear actuators can be mounted in various ways to allow different parts of the mechanism to move.

Through building these models, I learned what needs to be constrained, and what cannot in order to achieve a particular motion.

I was able to replicate the motion of a pneumatic cylinder by making cylinders out of straws with small dowels inside to act as the plunger. I then used cardboard to create clevises to connect the cylinder onto the mech. Every cylinder "works" in the sense that it extends and retracts like it would on full-size build.

These models are built using craft-sticks, dowels, cardboard, and straws.

Stage Dioramas

I make animatronic show stages for fun at various scales to display figures. I started with the "Rock-afire Explosion" 3-stage, and went on to make more.

To some, model-making is just about creating a visual representation of something at a smaller scale. To me, model-making is an opportunity to test my understanding of engineering principles as well.

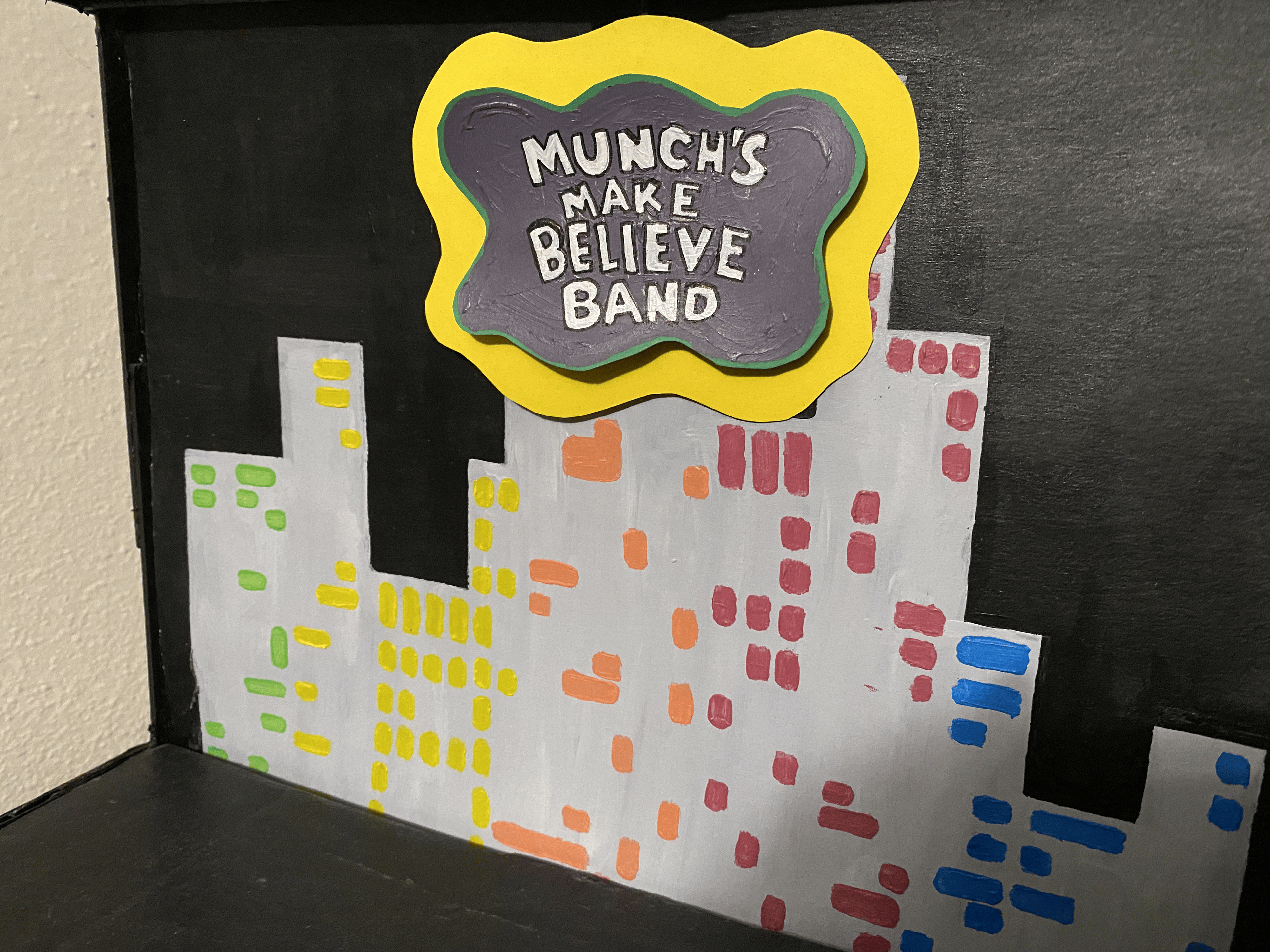

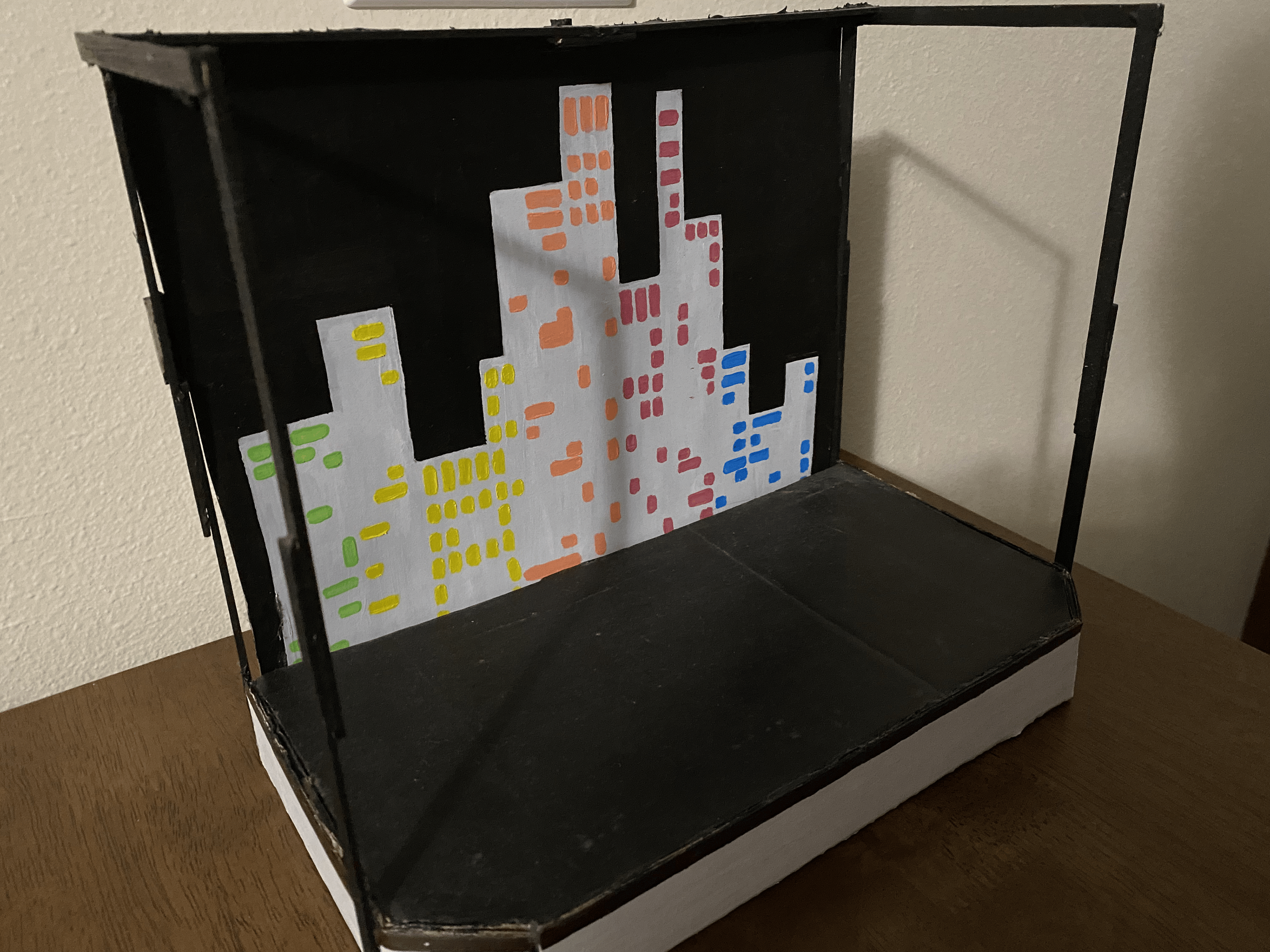

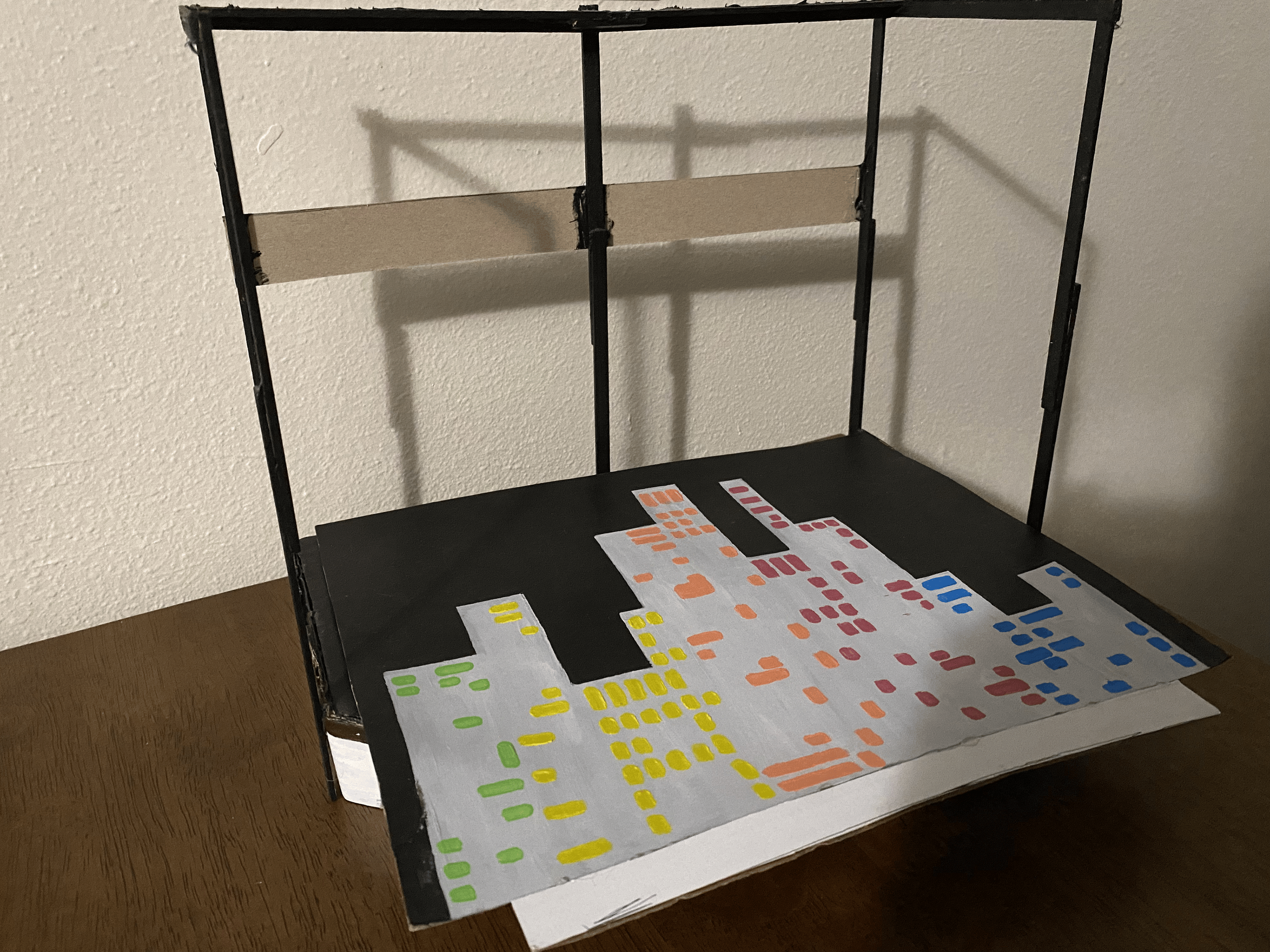

All of my dioramas are built with modularity and structural integrity in mind. I like to build with the intention of being able to easily change out accessories without causing permanent alterations to the model.

"Rock-afire Explosion"- Showbiz Pizza Place 3- Stage

The stage features intricately hand-painted accessories and backdrops. Every accessory is built to scale with reference to actual measurements. I like to get creative with how I go about the attachment points of each accessory.

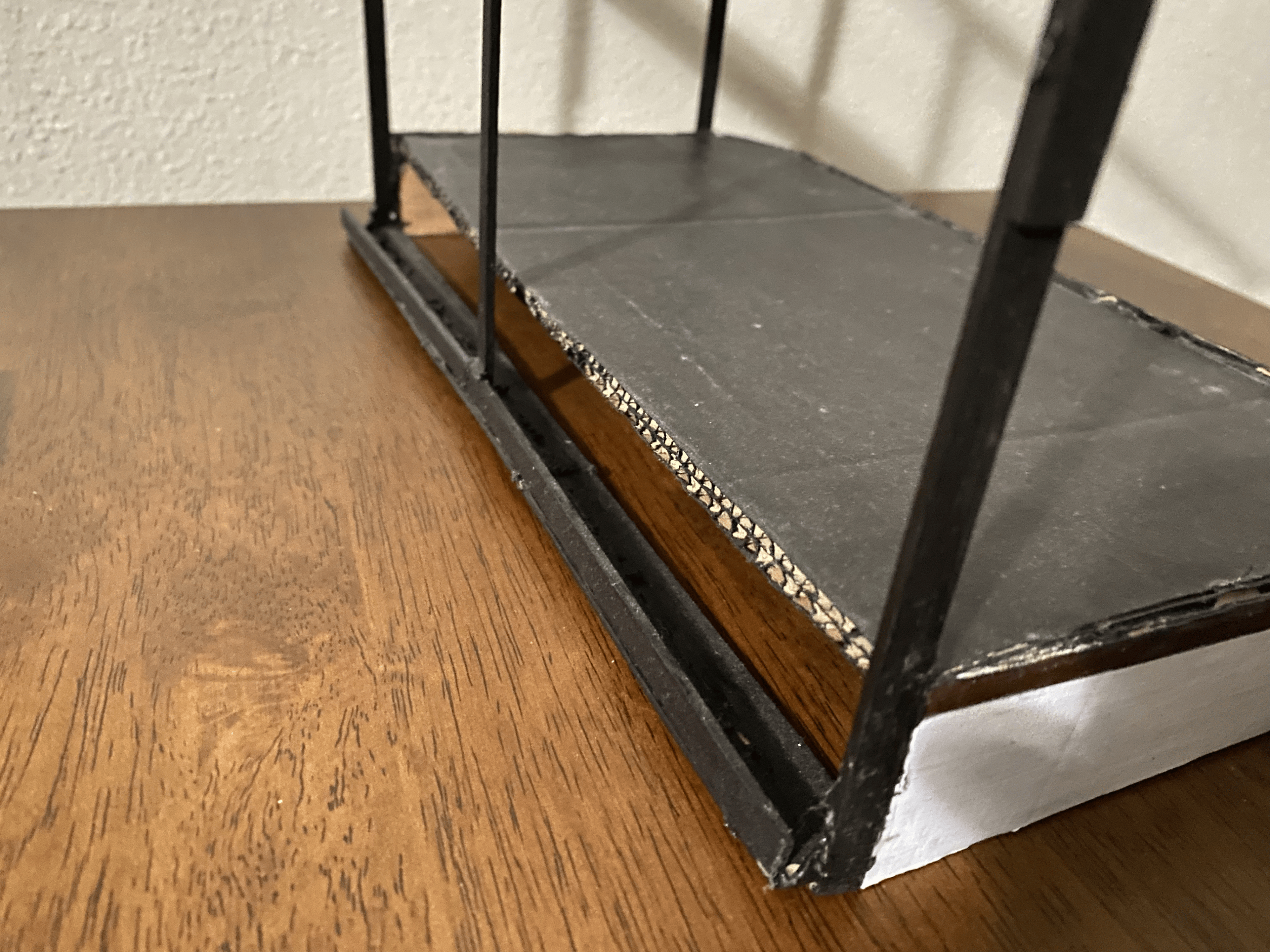

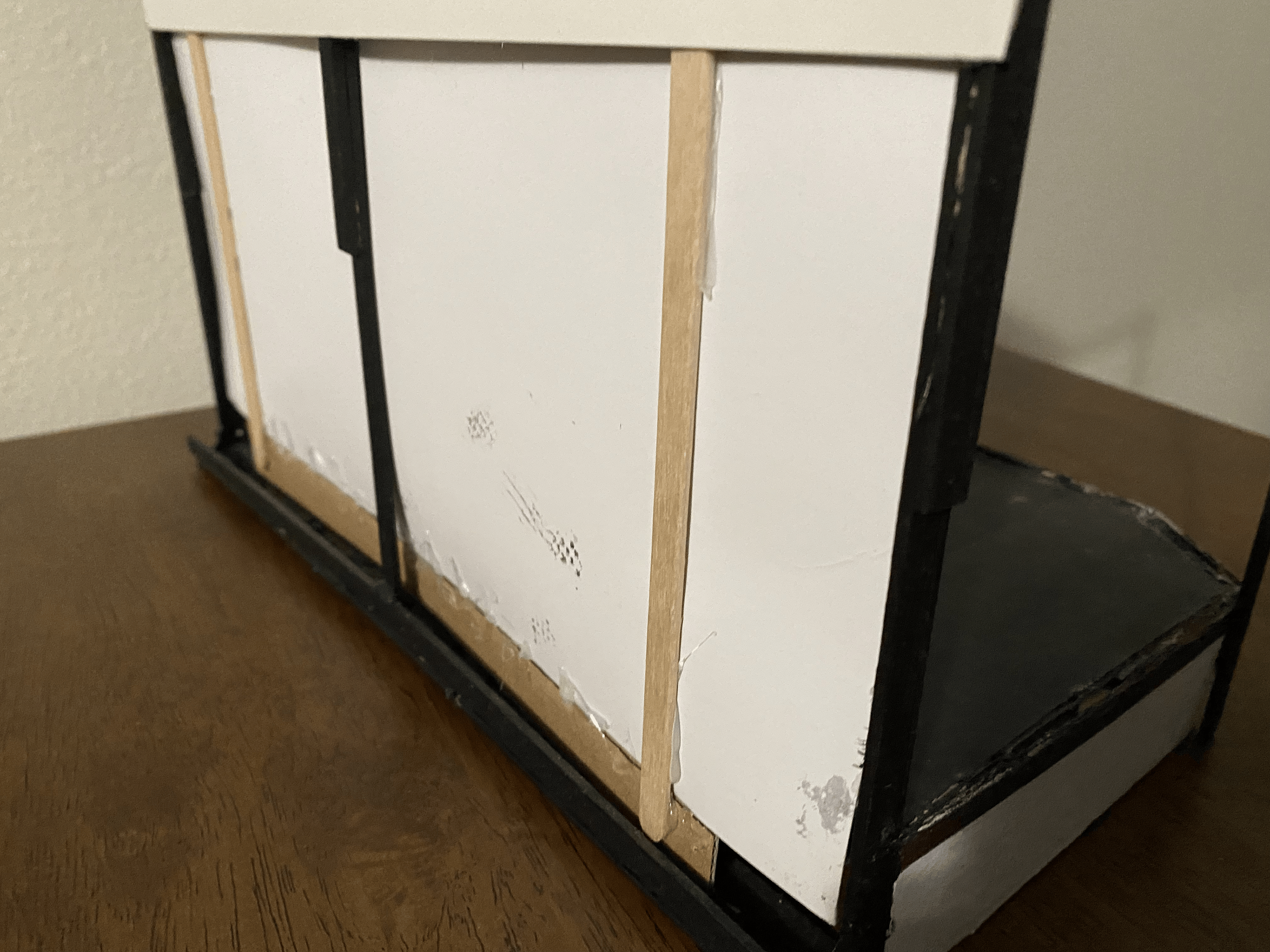

The back of the 3 stages have built in "slots" to allow for easily changing out backdrops. The "Rock-afire Explosion" sign, as well as other signage is designed to hook onto the top of the backdrops. The diorama is essentially a bare frame that can become anything when custom backdrops and accessories are added to it.

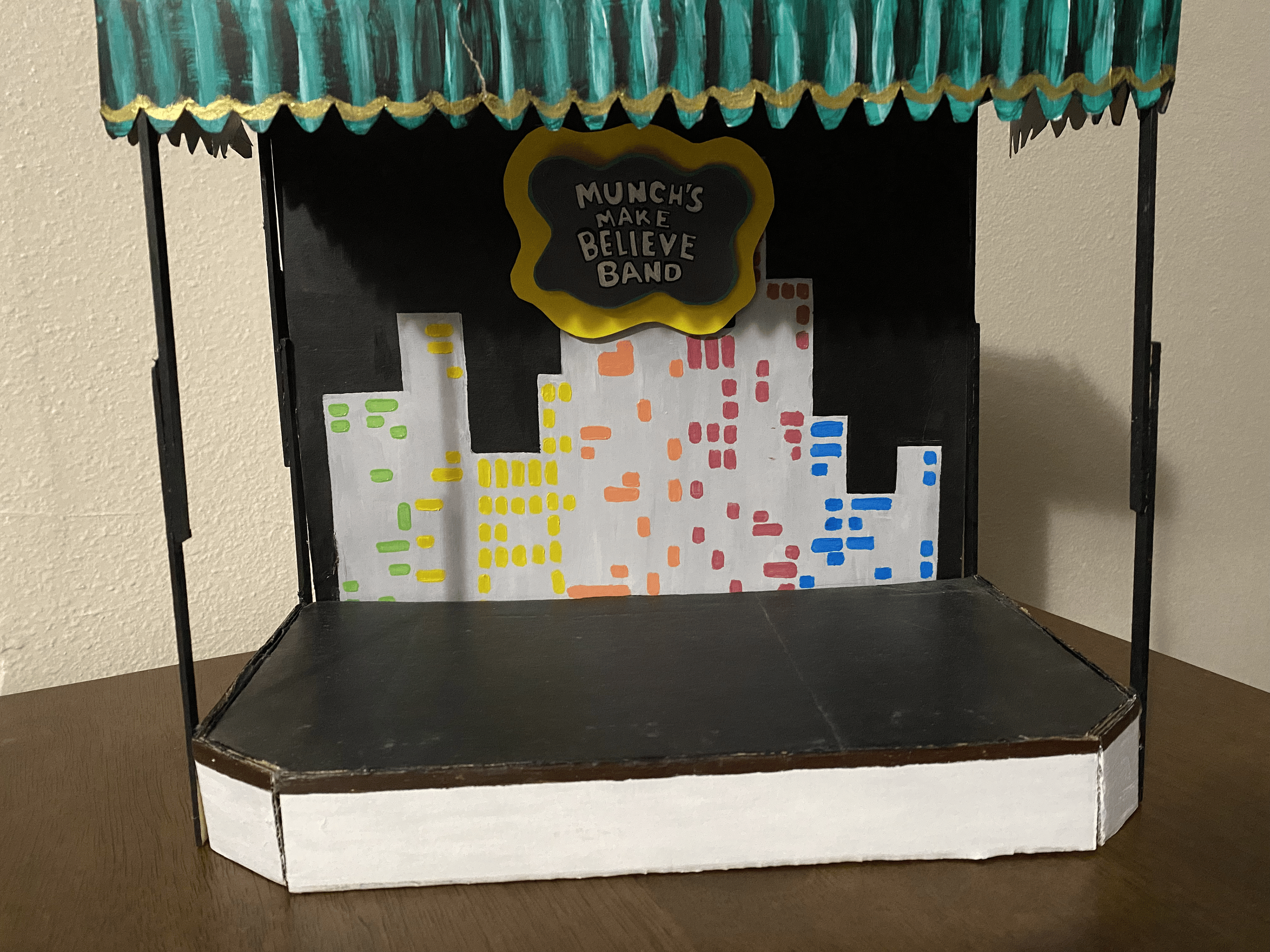

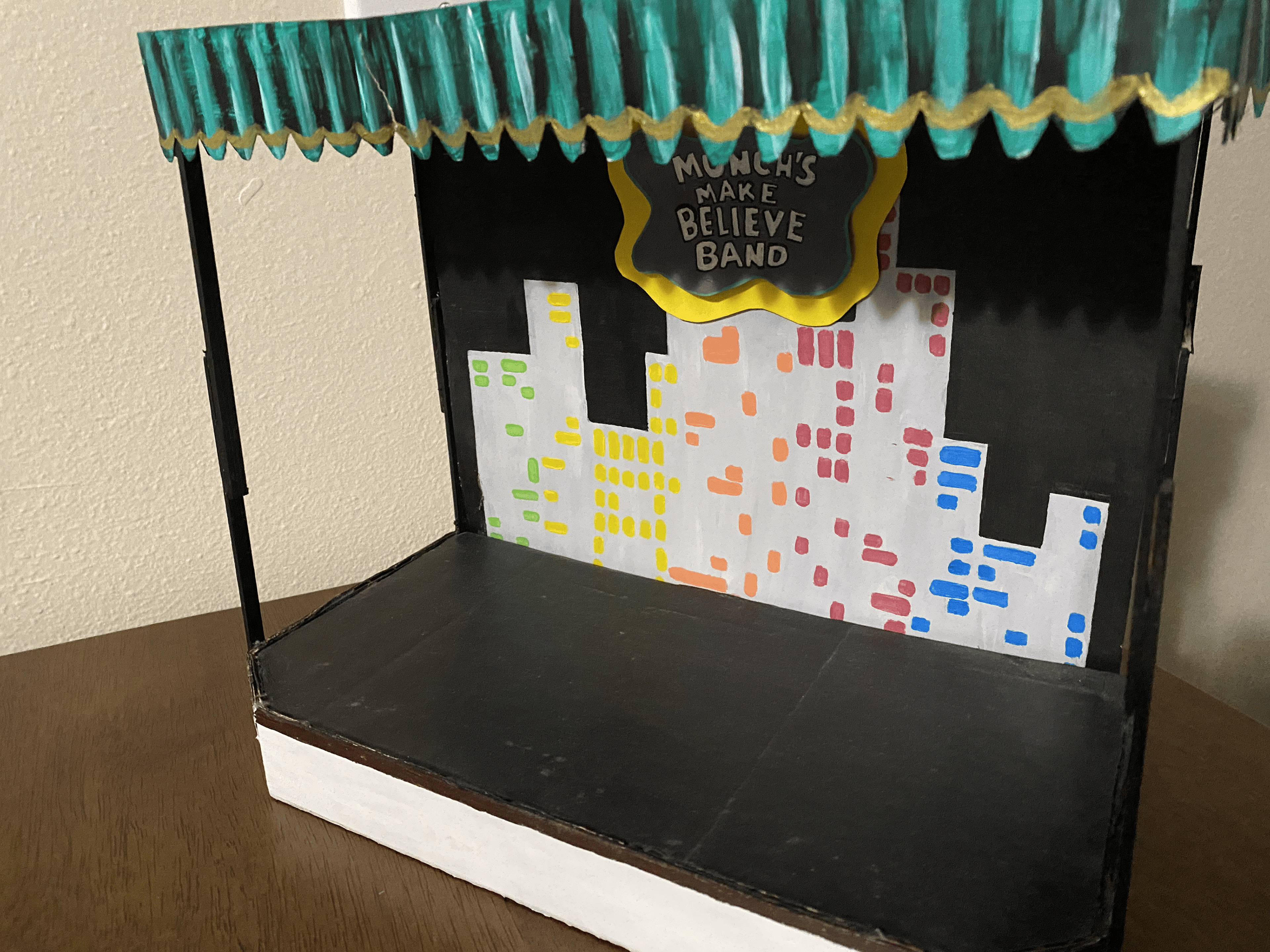

"Munch's Make Believe Band"- Chuck E Cheese's 1- Stage

I am always experimenting with new model-making techniques, so that my builds look clean and professional. I use simple supplies like cardboard, paper, wood sticks, dowels, and acrylic paint when making models at home as a hobby.

"Five Nights at Freddy's"- Movie 1- Stage

(My portfolio is intended to provide examples of my various skillsets, and to get to know me as an artist; therefore, the selection of work shown is casual and not crafted to suit any particular need.)