(Ask to see private professional Toy Design portfolio for projects not disclosed to public yet)

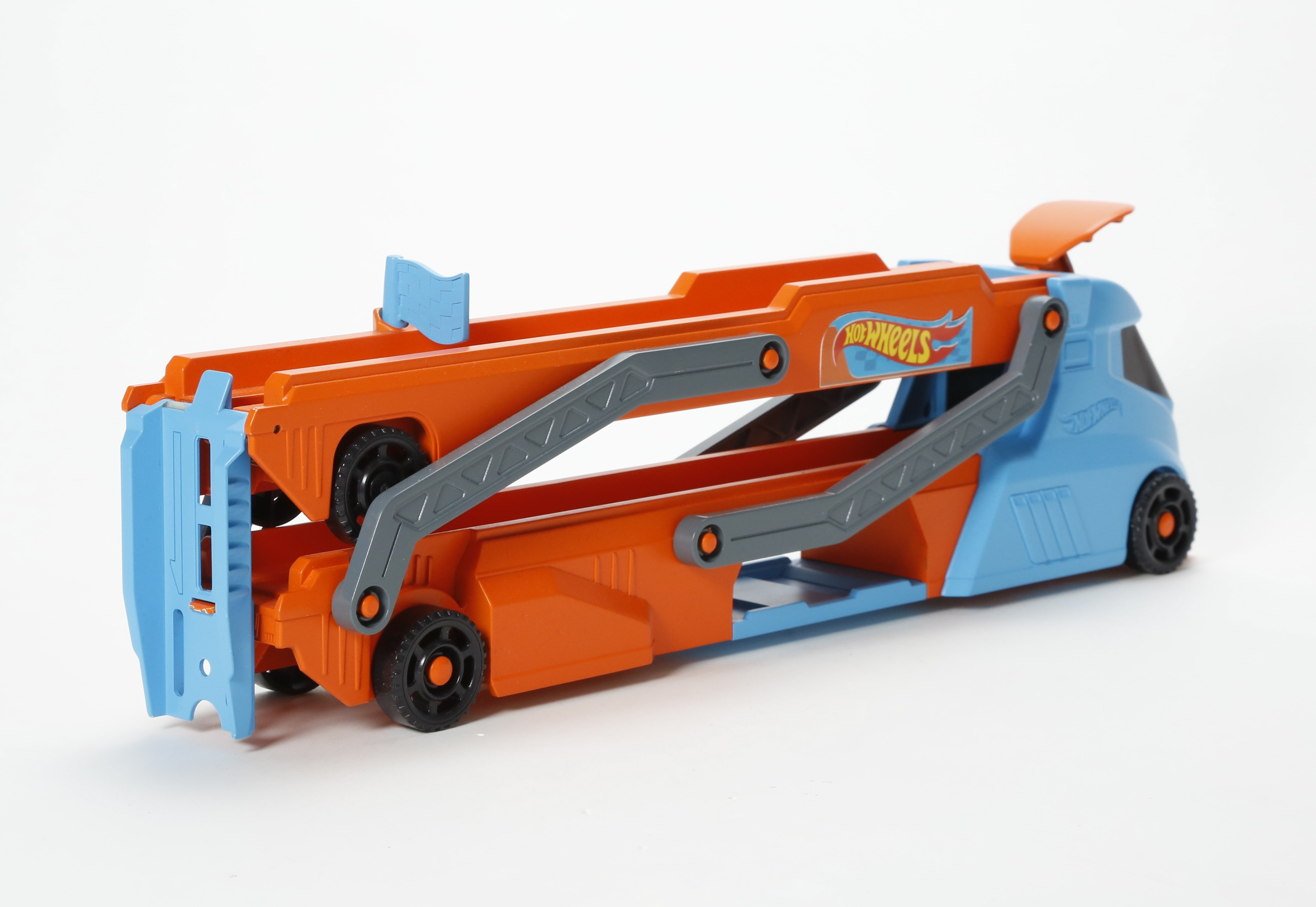

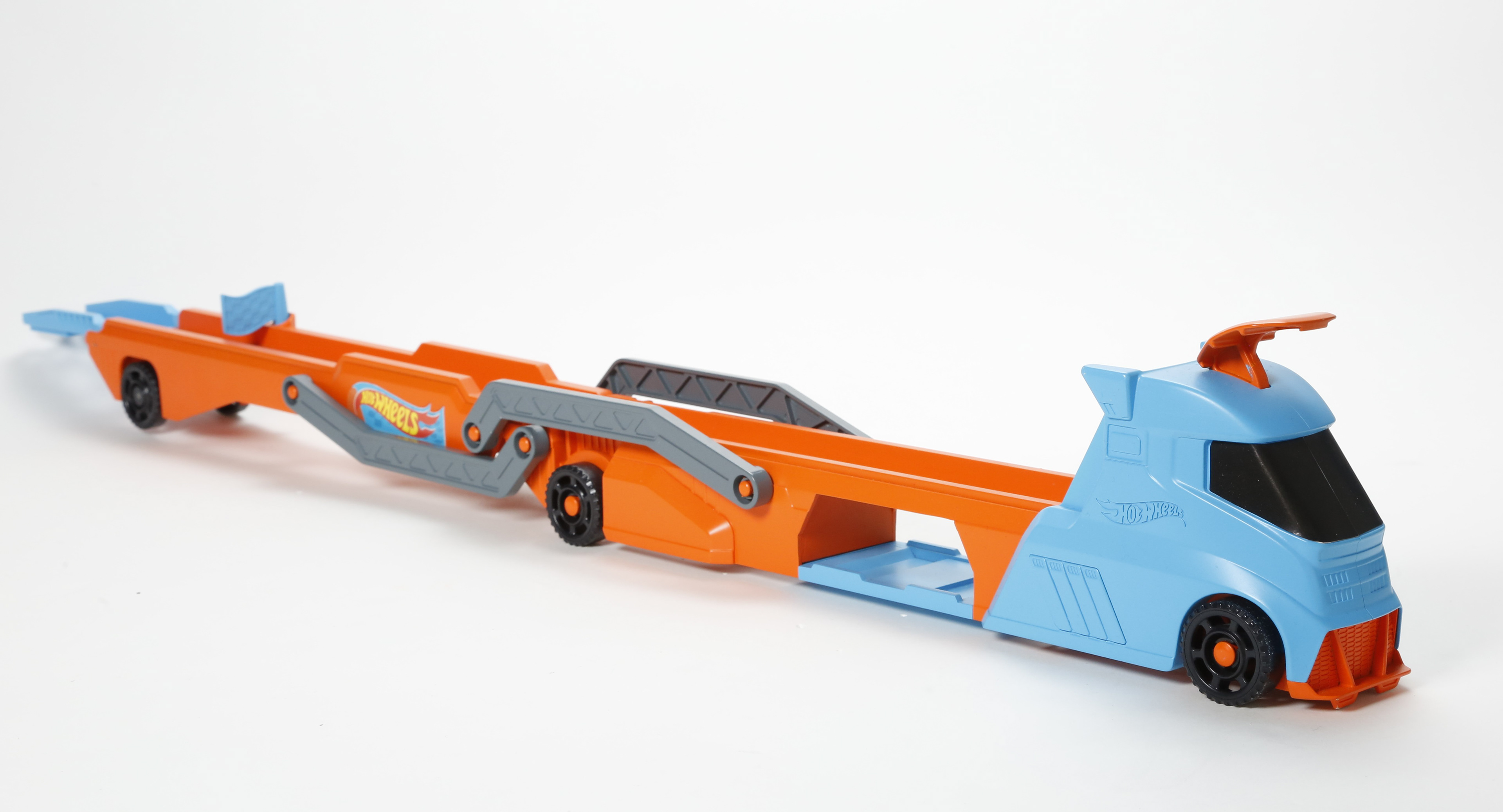

Hot Wheels Fall 2024 EC Hauler

This was a project during my 2023 internship.

It is not common for an intern to have a toy approved for production, but I was fortunate to be there at a time where they had a "late add" to the following year's release. I took this opportunity to come up with something worth an approval to get my name in the game.

Deliverable:

Design a Hot Wheels Car Hauler that is within the $14.99 MSRP price range, holds at least 9 cars, and has a unique Hot Wheels "transformation action".

Outcome:

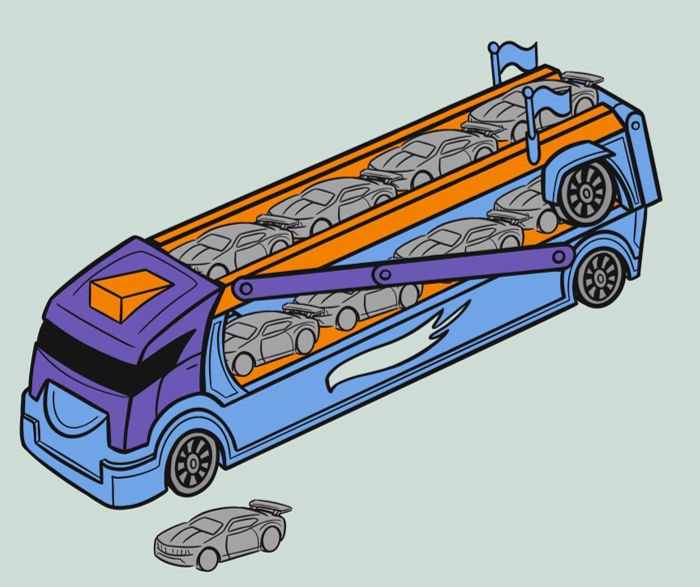

I came up with many concepts for a hauler that fit this criteria, and ultimately my "Extend N Stunt" Hauler- name changed to "Speed Track Transporter" was the chosen design!

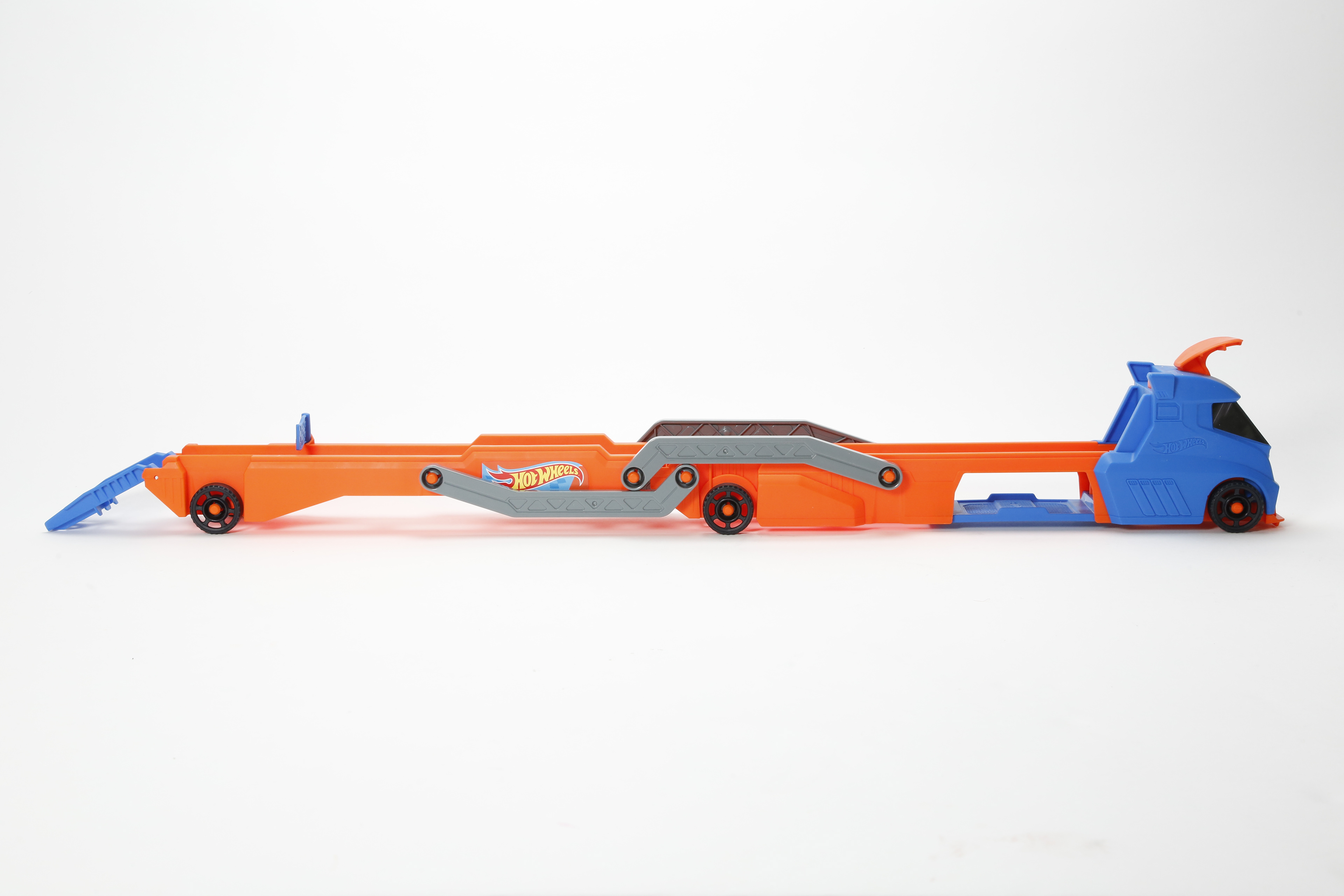

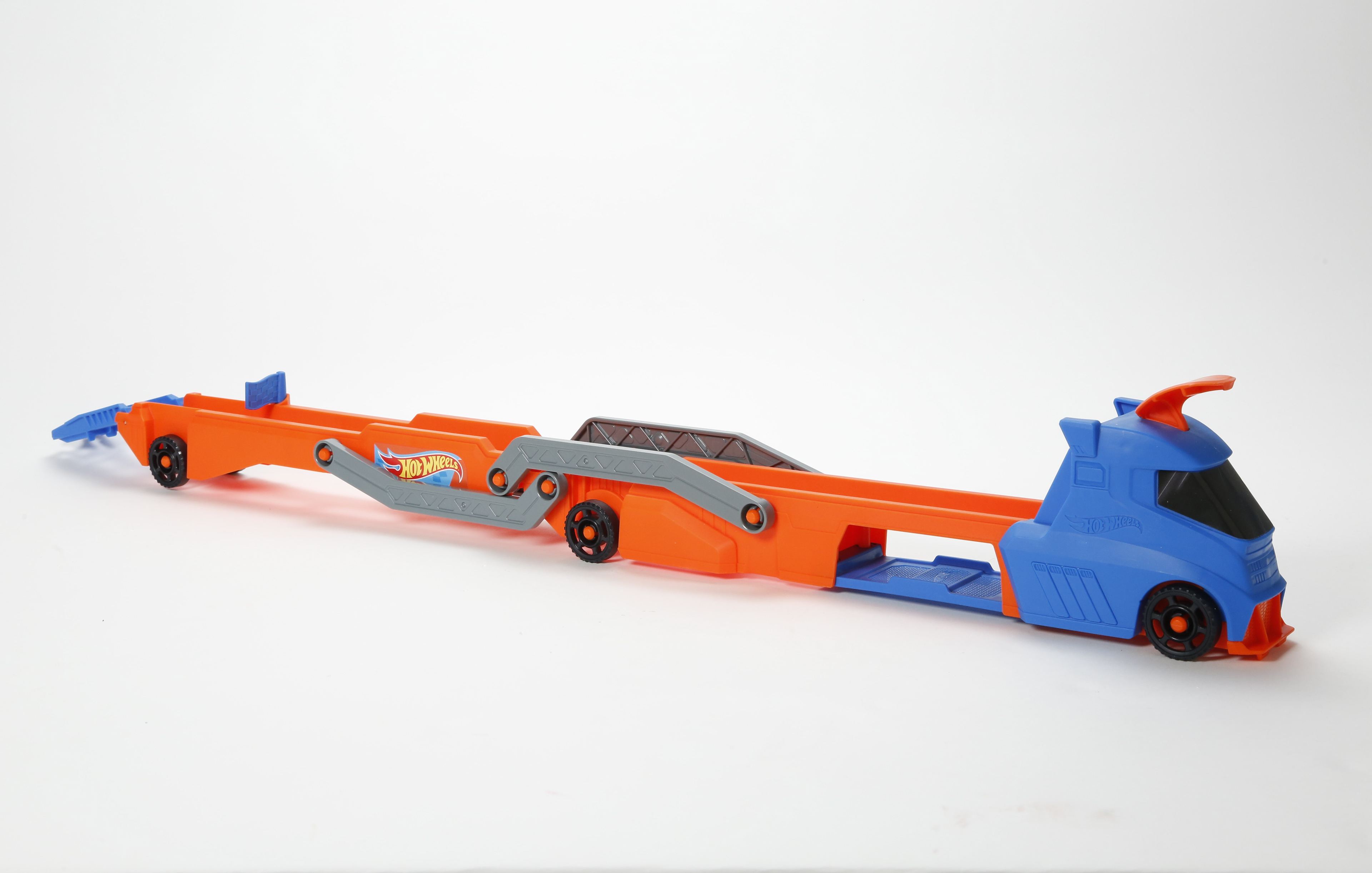

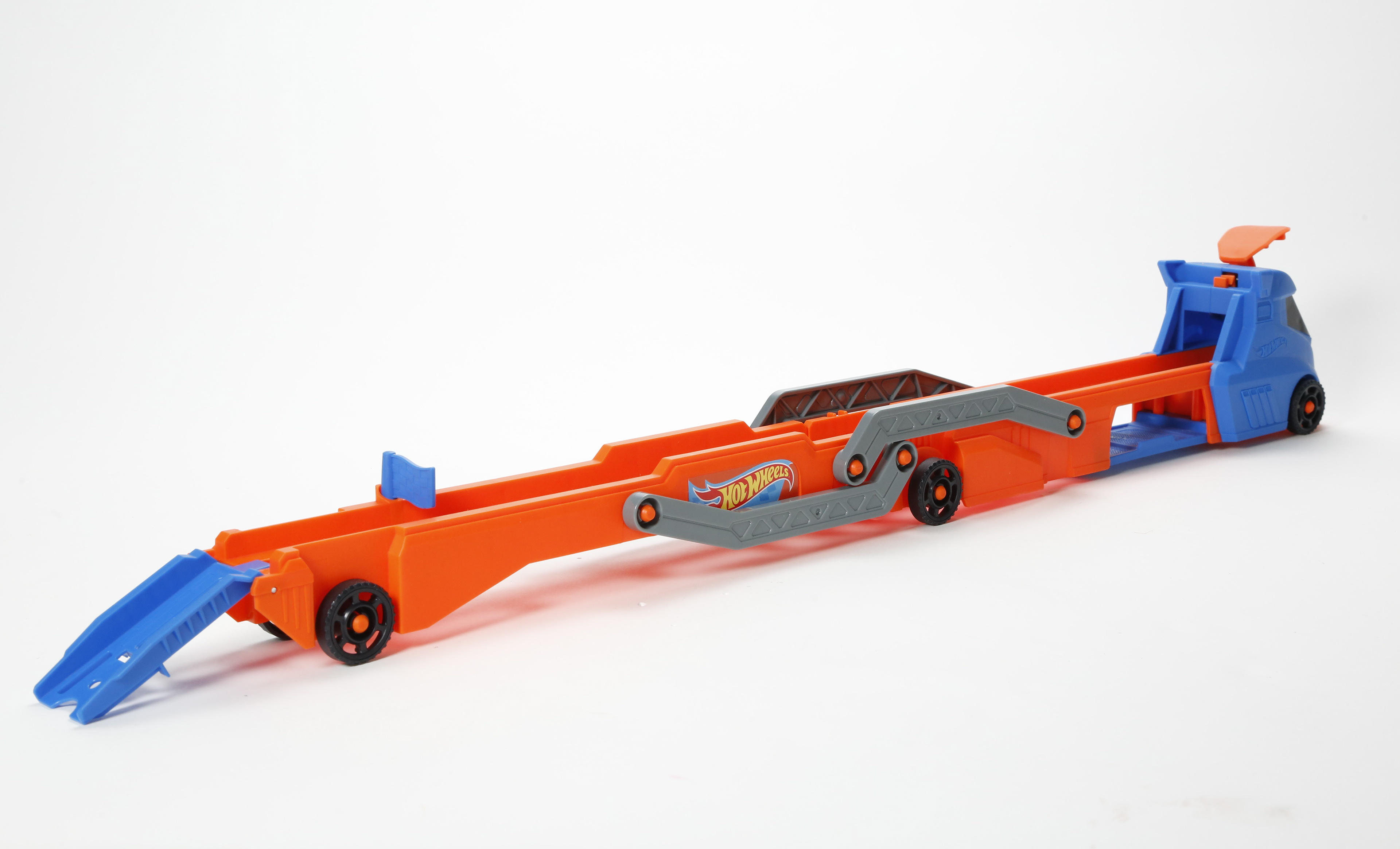

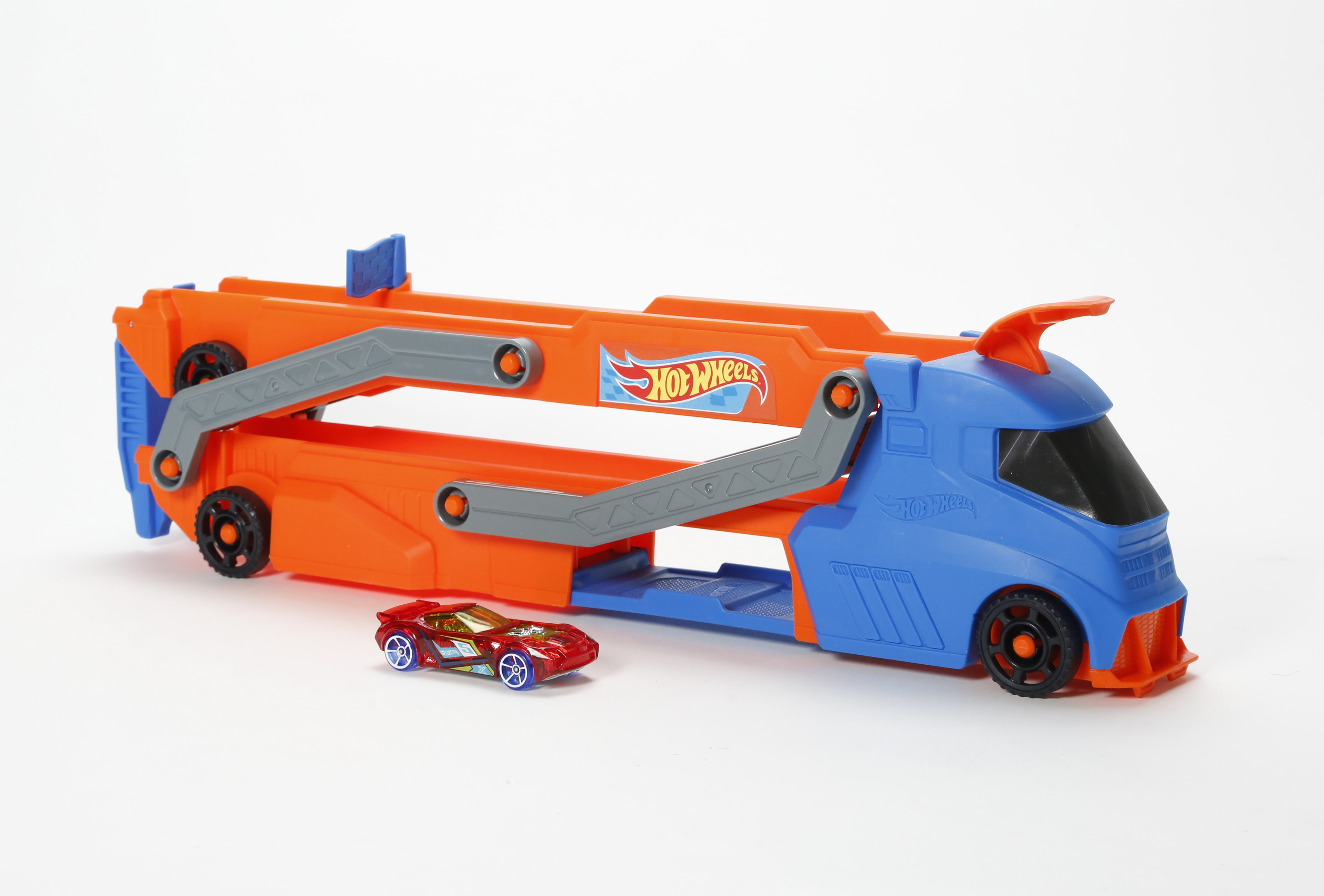

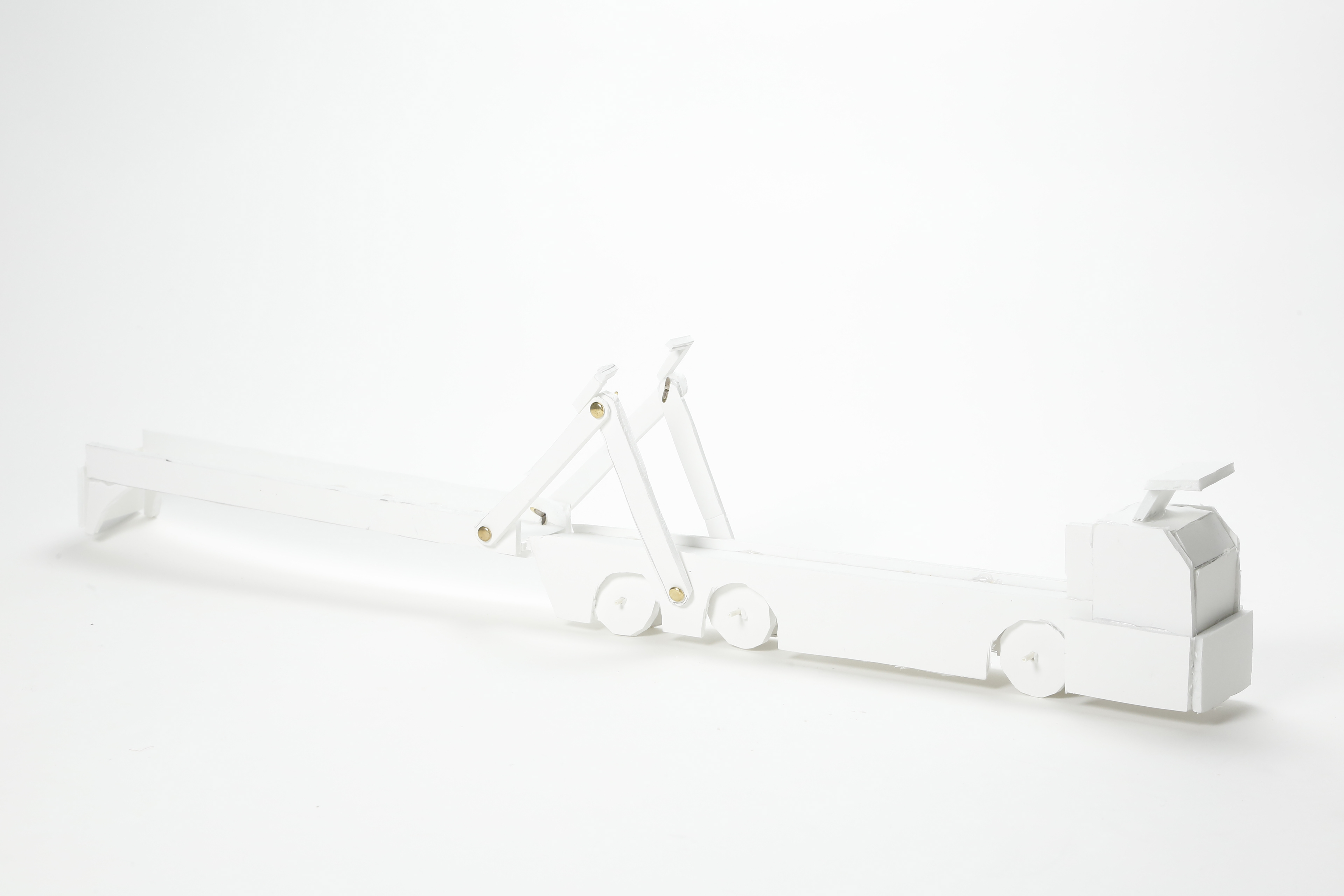

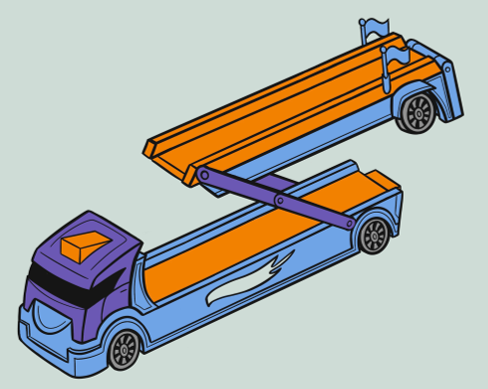

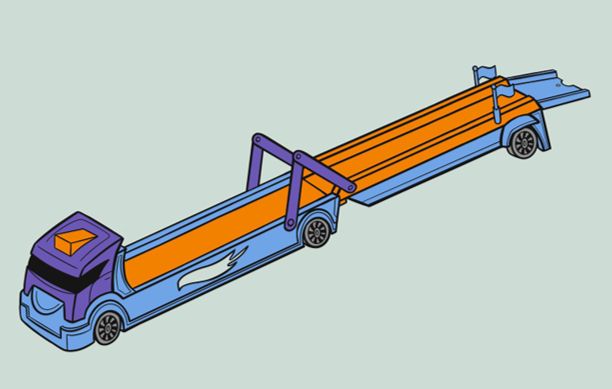

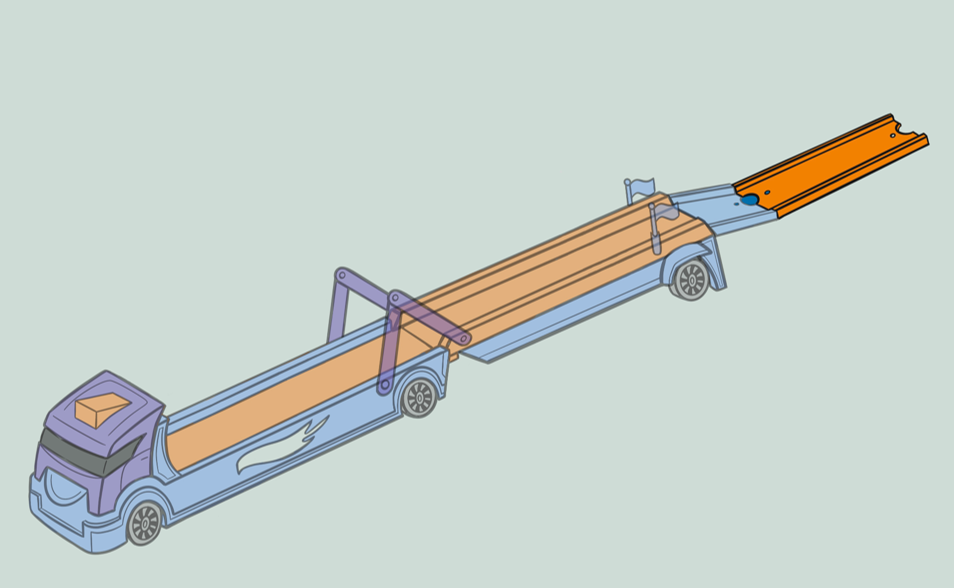

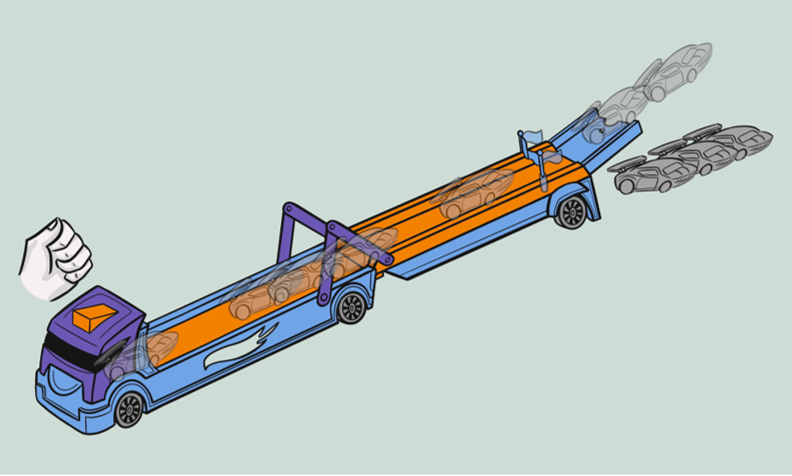

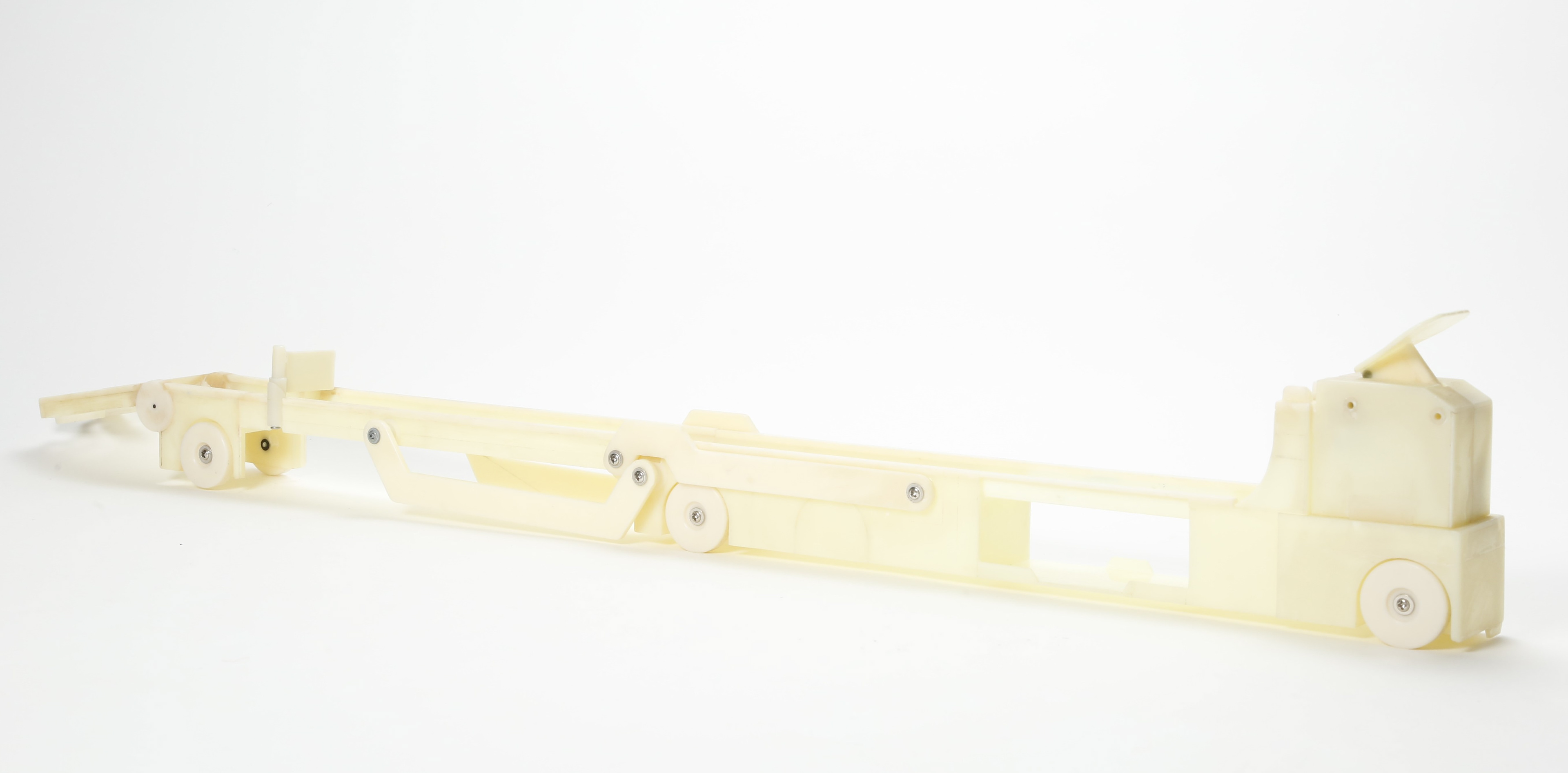

The "Speed Track Transporter" holds 11 die-cast cars, transforms into one long race track that can have additional Hot Wheels track added to the end, and cars can be launched from the cab down the track.

What makes this toy extra cool, is that it can transform from its double-decker state to a single-lane while keeping all cars on board, something other haulers like this do not do.

It can also still drive while in its transformed state due to the additional wheels added to the end of the trailer, something else that separates it from other car haulers made in the past.

Because Hot Wheels already has a large portfolio of haulers, it was important to be innovative!

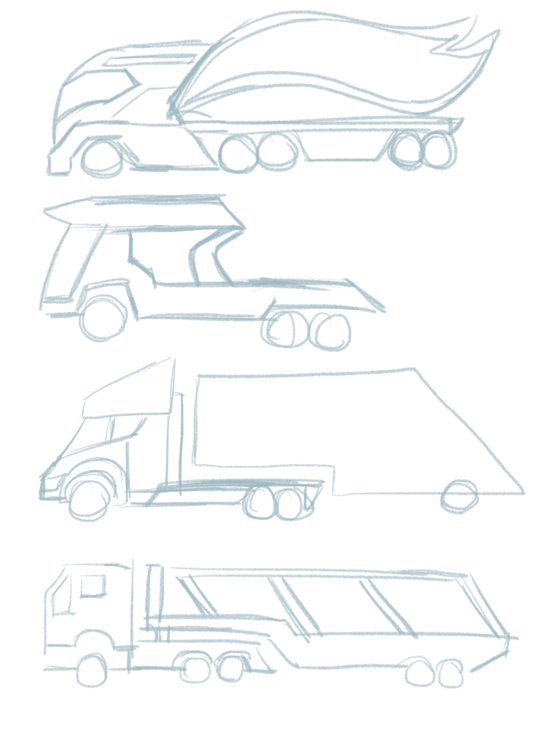

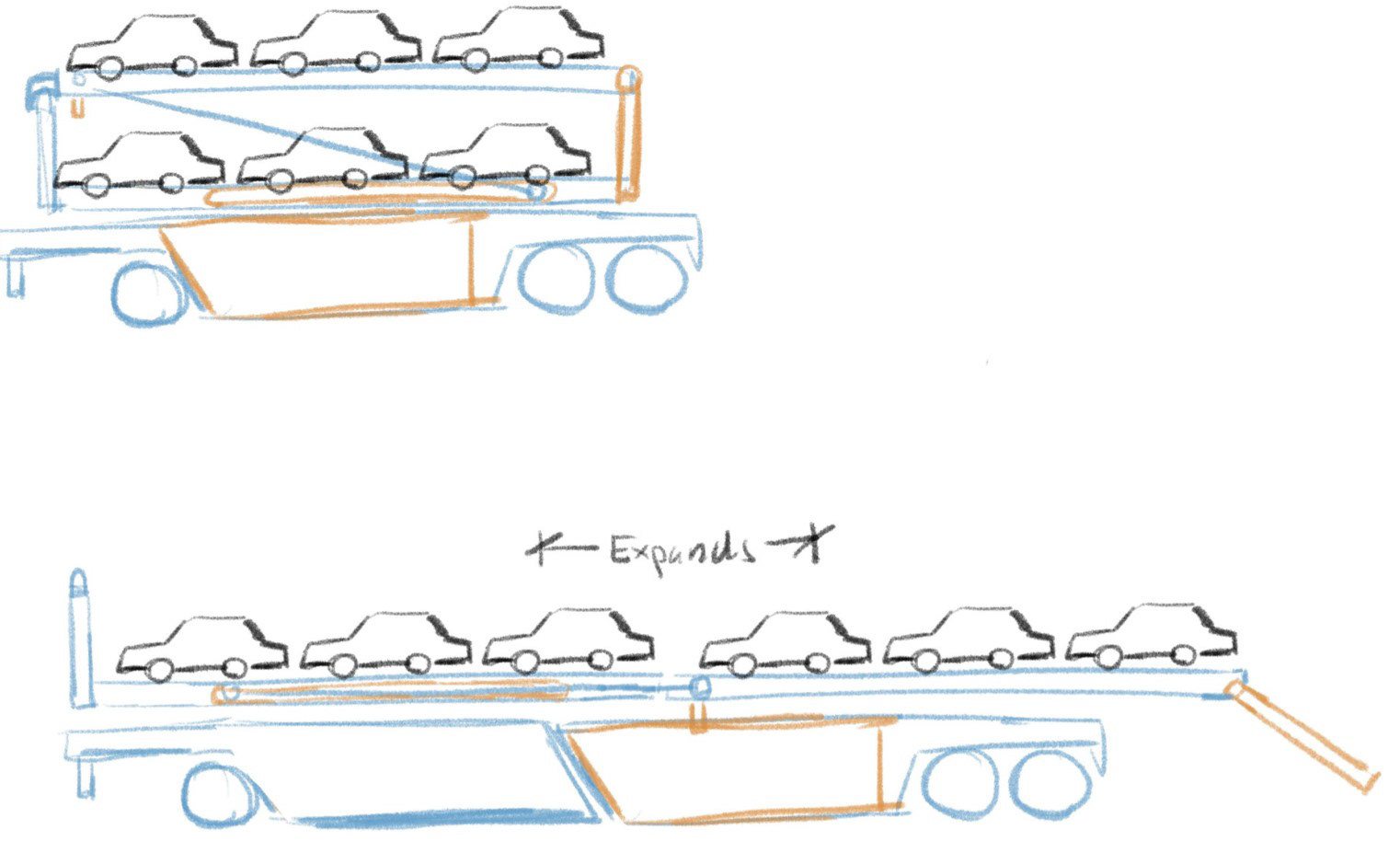

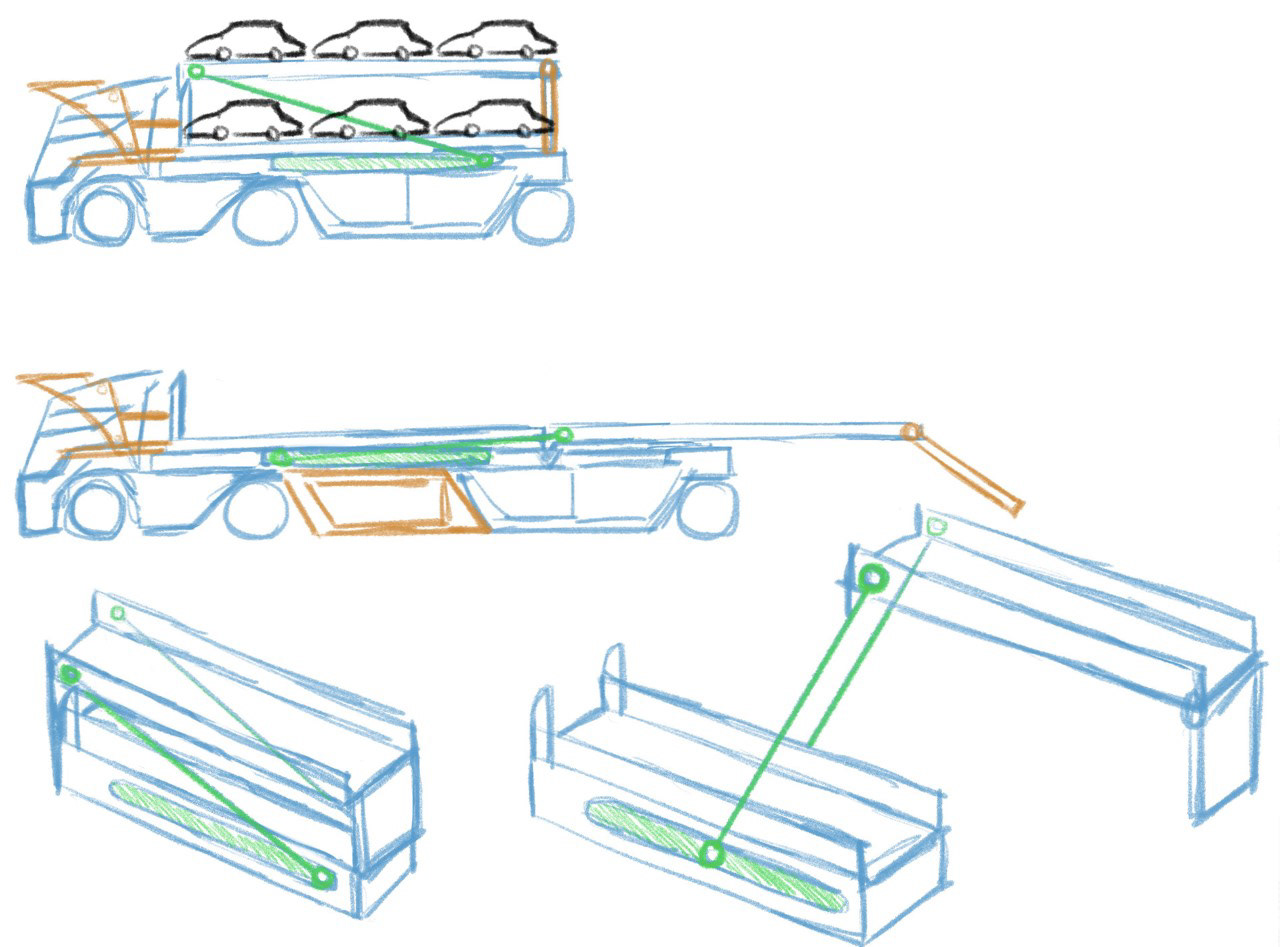

Brainstorm Phase

Brainstorming happens during the first week of receiving the project.

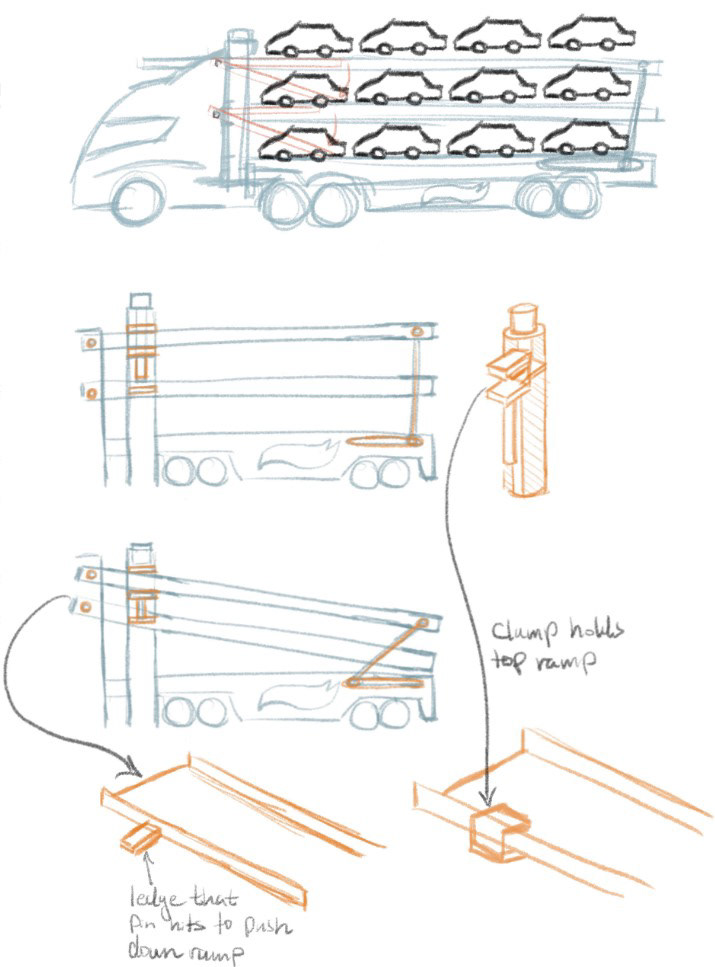

I sketch anything and everything that comes to mind, no matter how good or bad of an idea it is. I create rough sketches of silhouettes, mechanism ideas, and general play features to communicate to others what I am thinking.

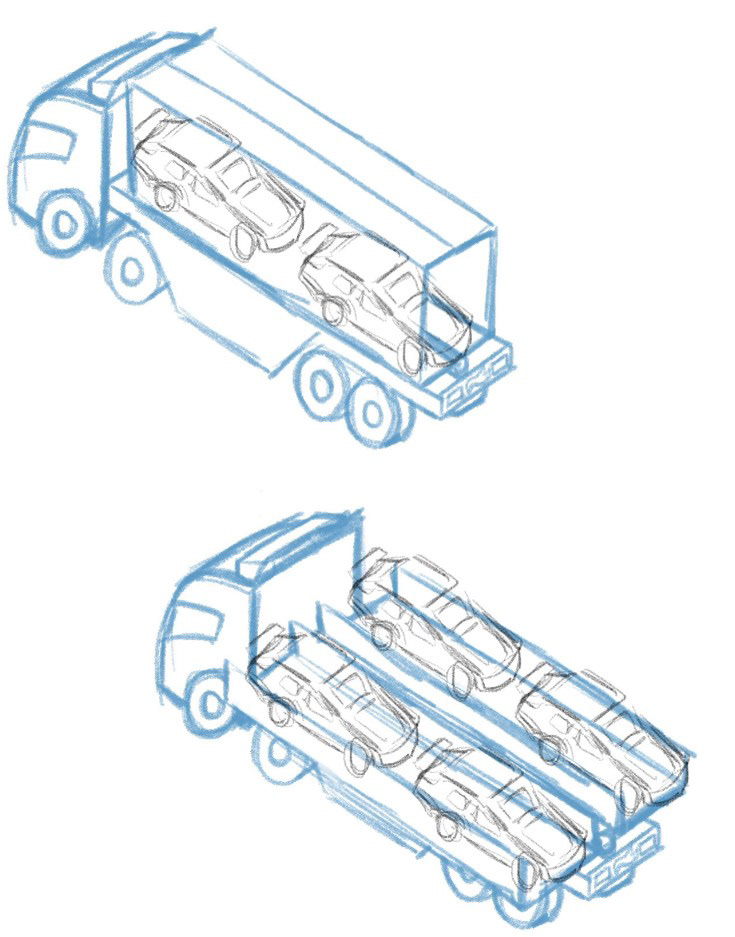

Silhouettes

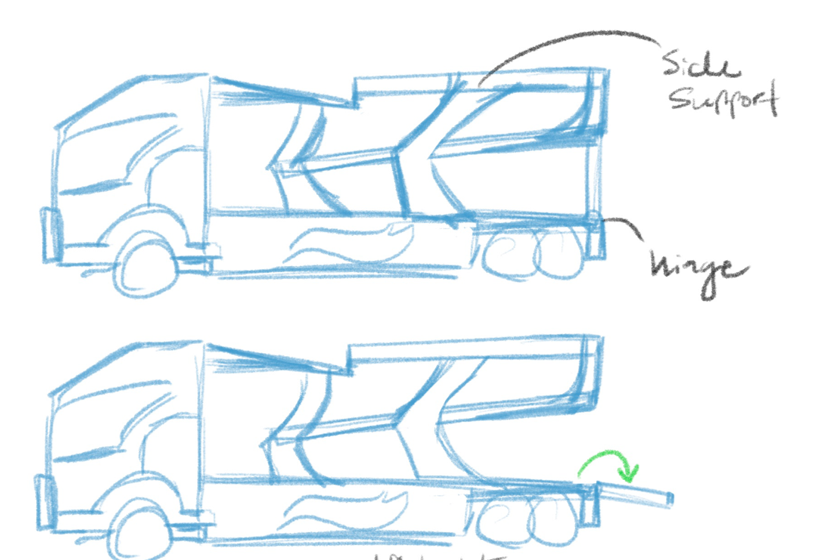

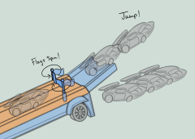

Tip mech. concept

enclosed trailer concept

double decker concept

launch from cab

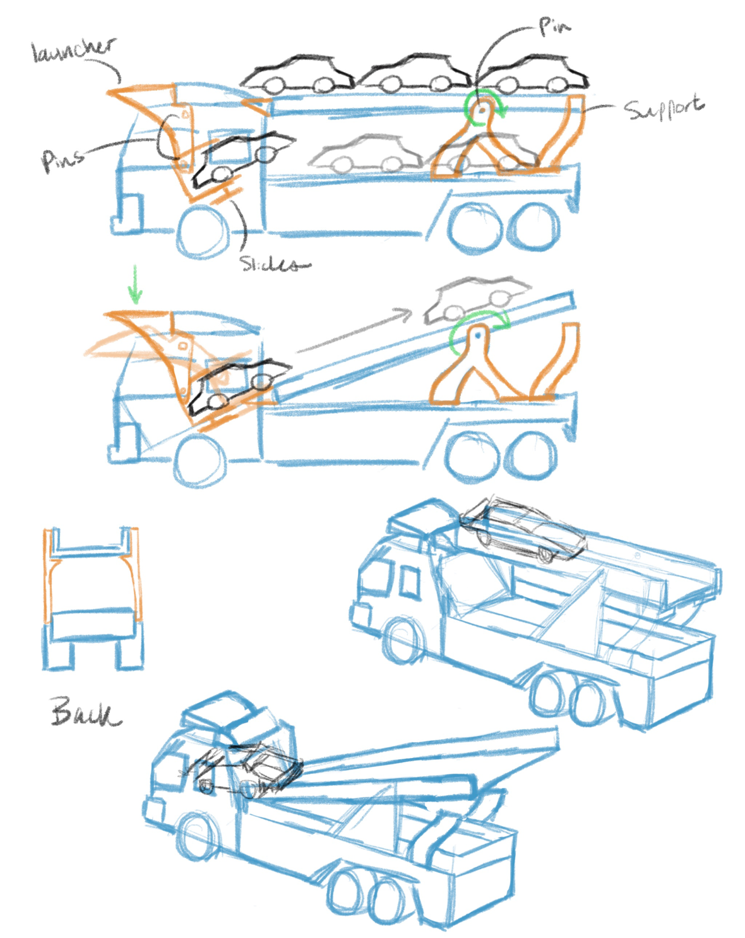

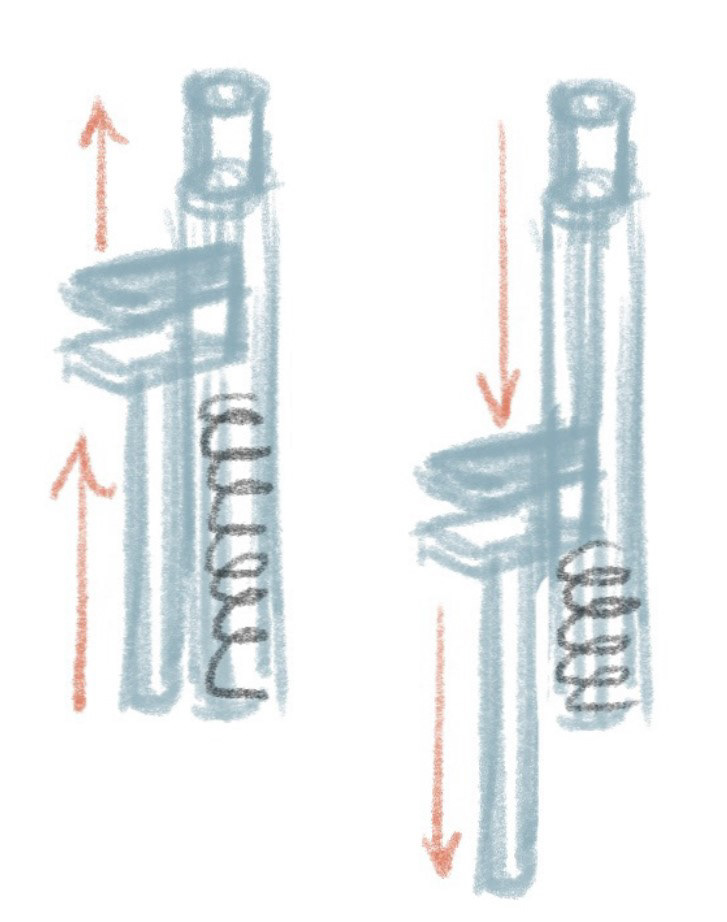

Spring Mech. concept

1st idea of extending hauler

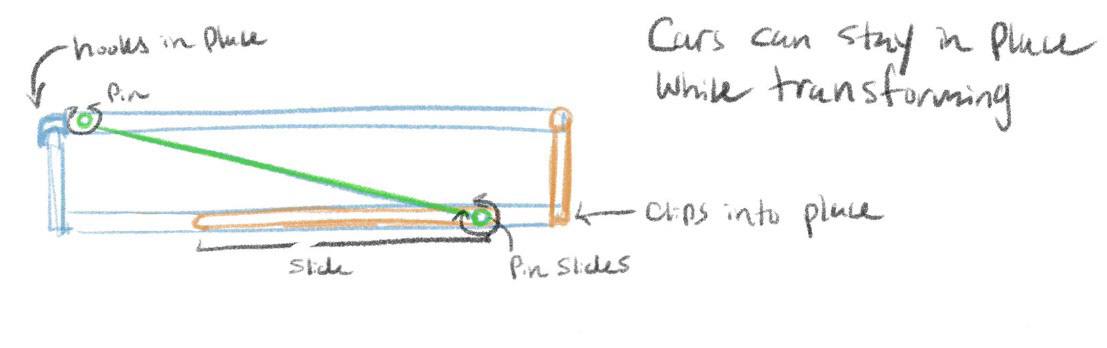

1st mech. design for extending hauler

1st mech. design for extending hauler

During this phase, logistics and cost are not to be thought about, as it often hinders the creative process early on. When brainstorming initial concepts, I try to think about how to make a toy really cool and unique, while maintaining the brand's iconic look. I also try to come up with unique ideas that have not been explored before.

Eventually, every drawing is presented to the design team and they will narrow down the pool of ideas to a select few.

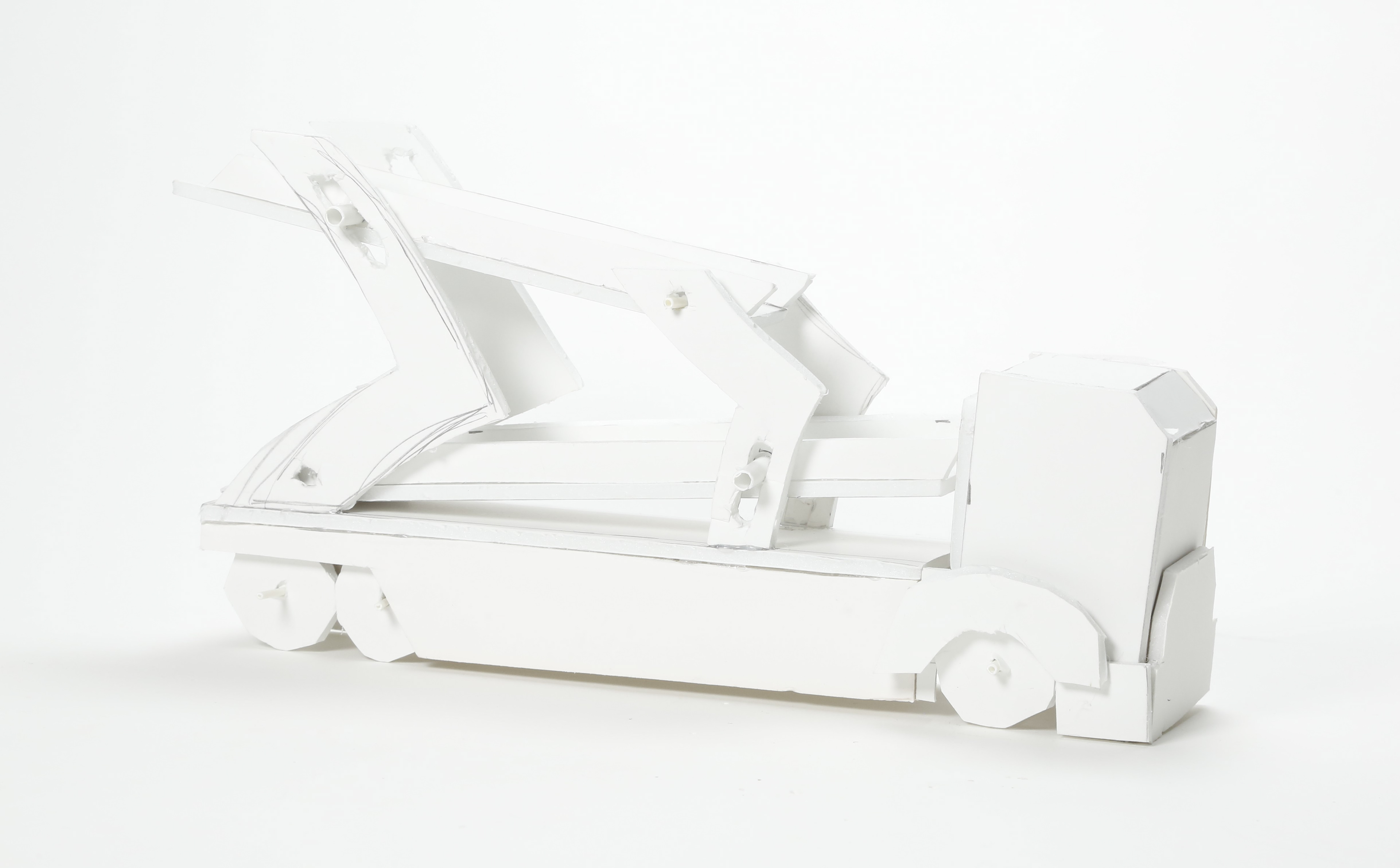

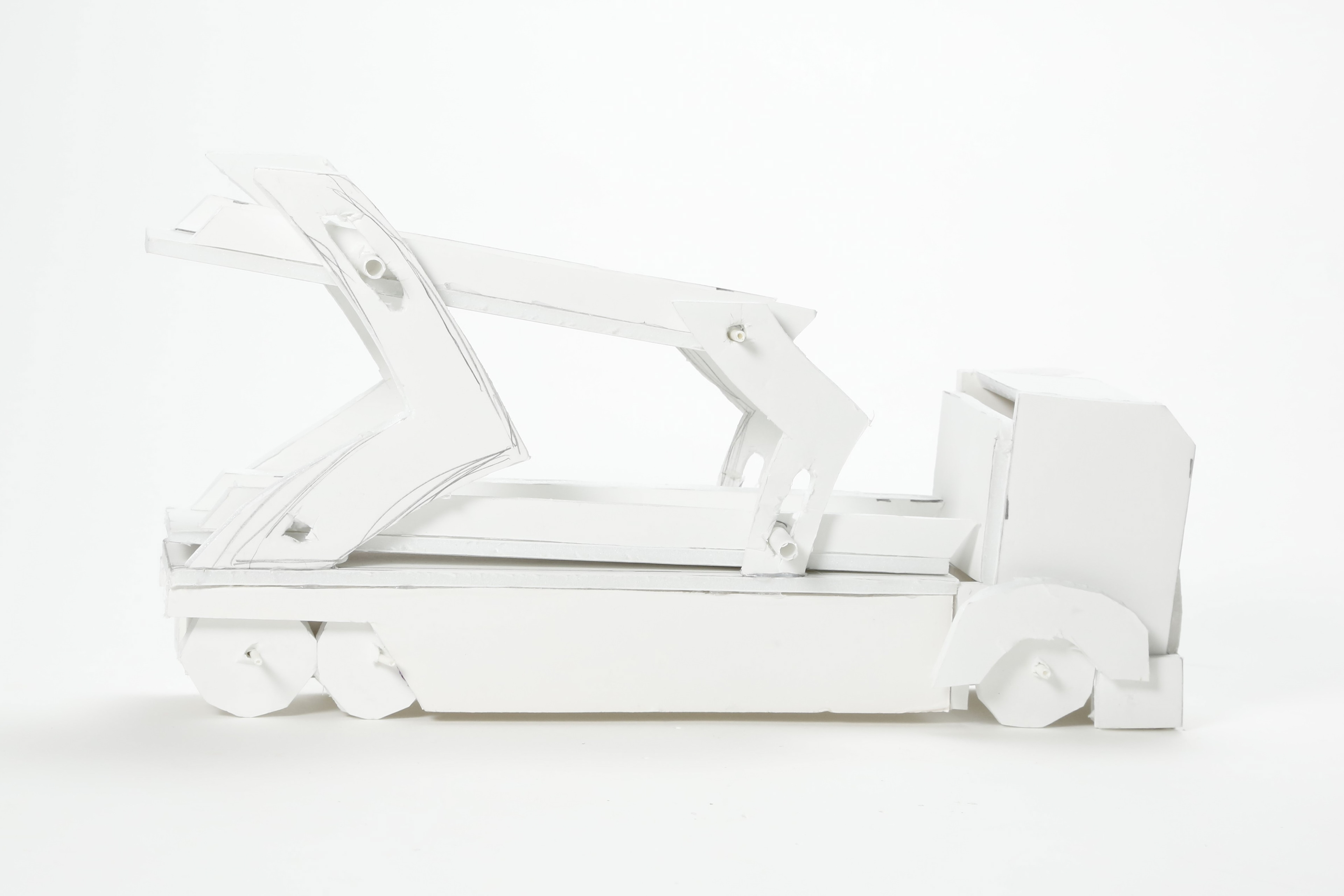

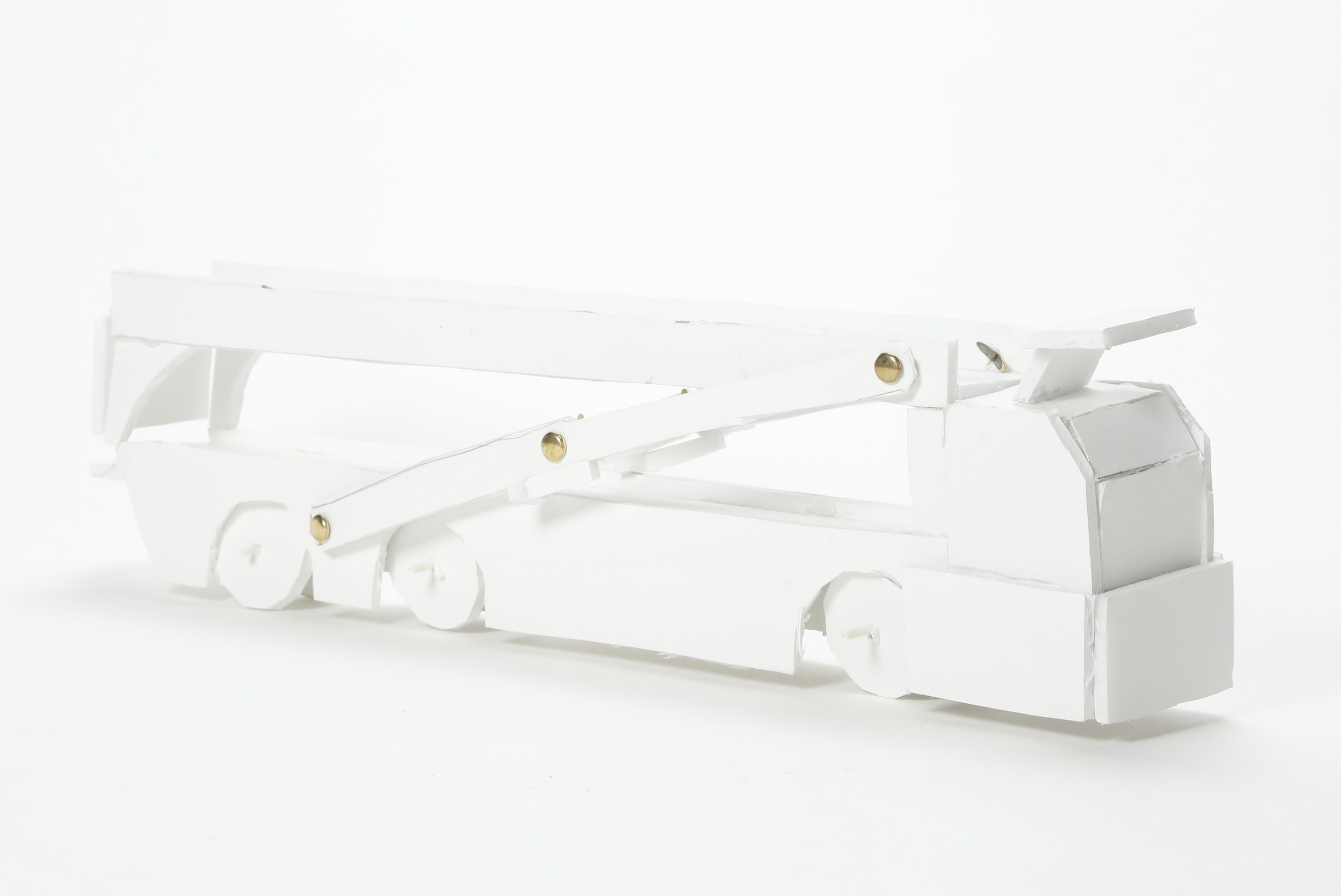

Foam Core Models

After my concepts have been narrowed down, I can now refine the chosen ideas. I will make foam-core models to depict scale and function to help others visualize what the product could look like.

Scaled models are incredibly helpful, as I have found that the model sometimes is more powerful than the accompanying illustrations when pitching a concept.

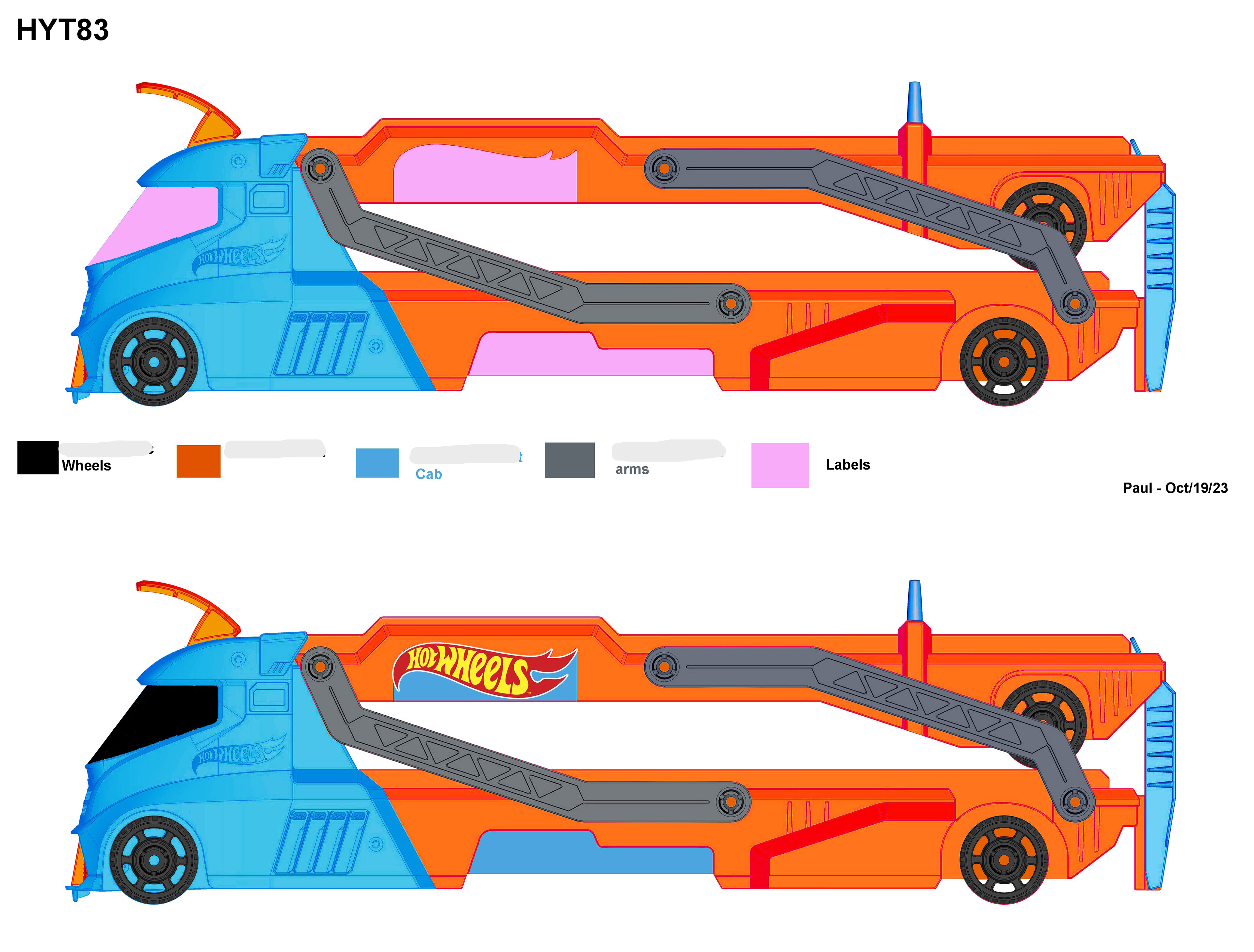

Final B-Sheets

During this final phase of the design process, the chosen design is illustrated to the fullest extent, including drawings to show scale and to walk through play. The drawings are then critiqued and adjusted accordingly through several sessions.

One thing I learned during this process, is some of the most creativity comes from having to come up with solutions on how to hit the target cost while still maintaining the key storytelling features of the toy.

Once illustrations are completed and the toy gets approved, it moves onto the production phase.

Just like the fully colored and rendered illustrations pictured, drawings of other concepts may also be finished to this extent, depending on how many the team is interested in moving forward with.

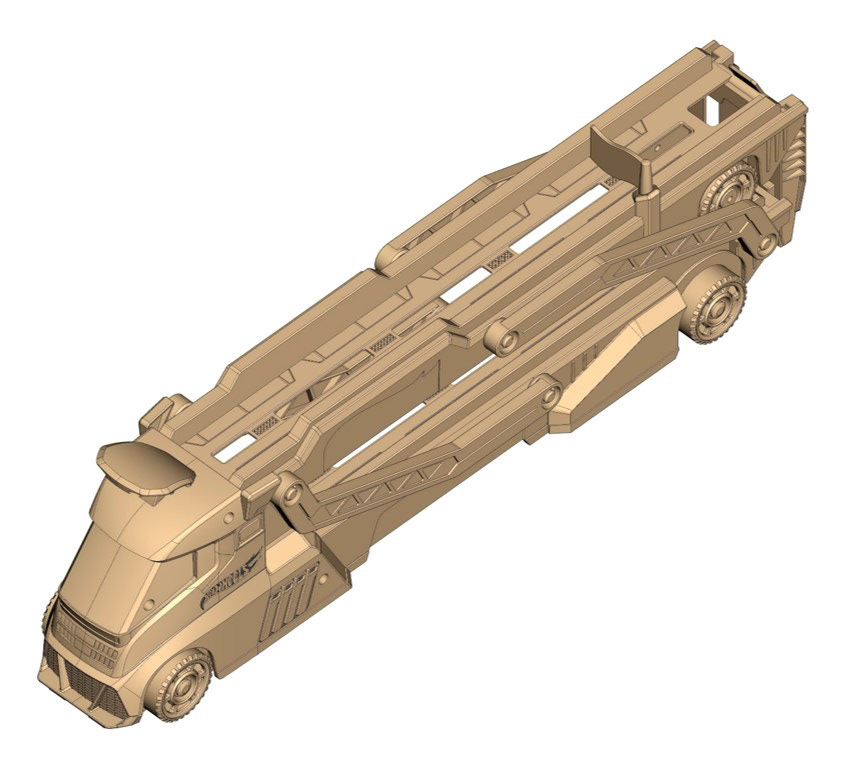

Production Phase

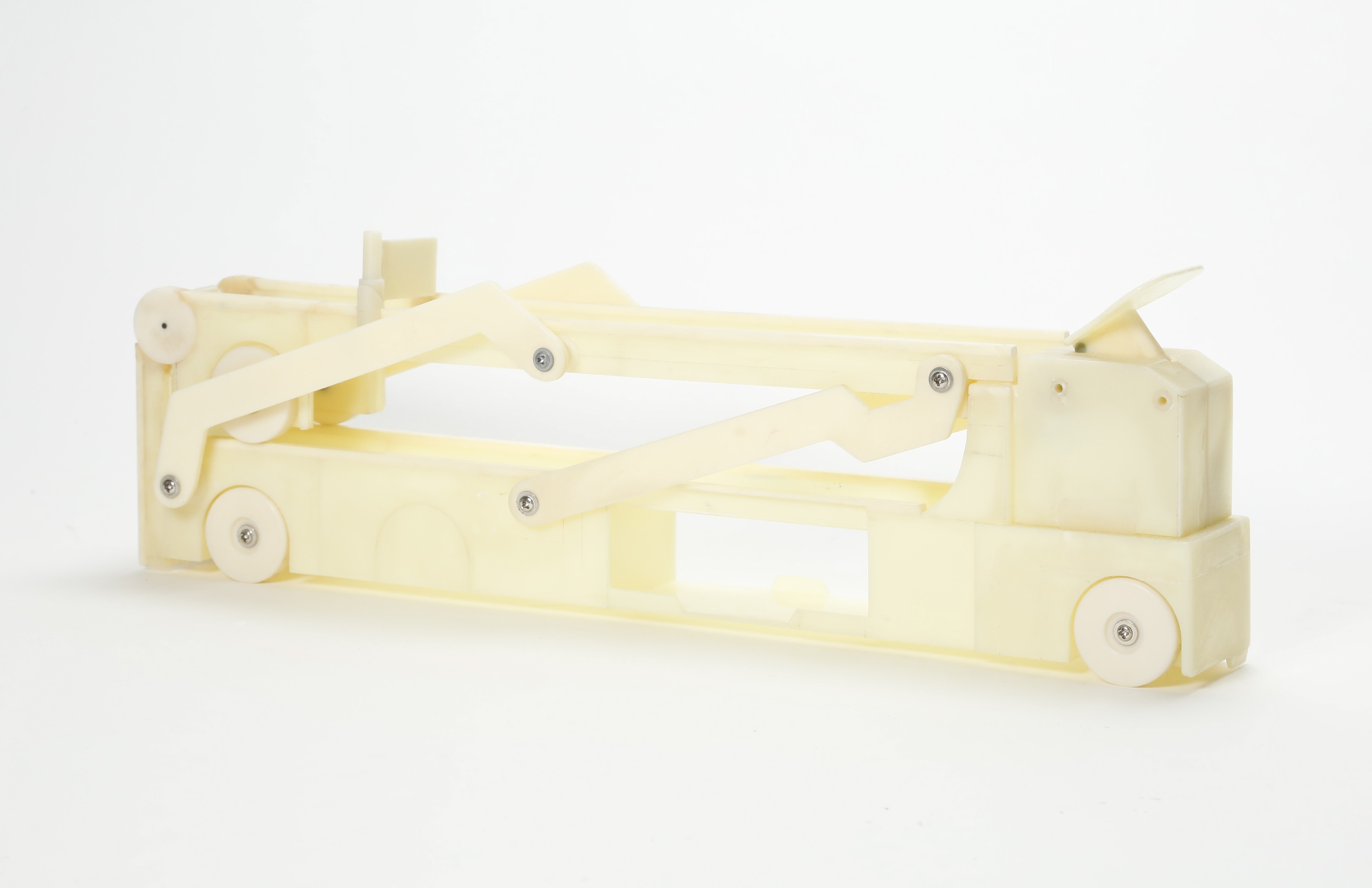

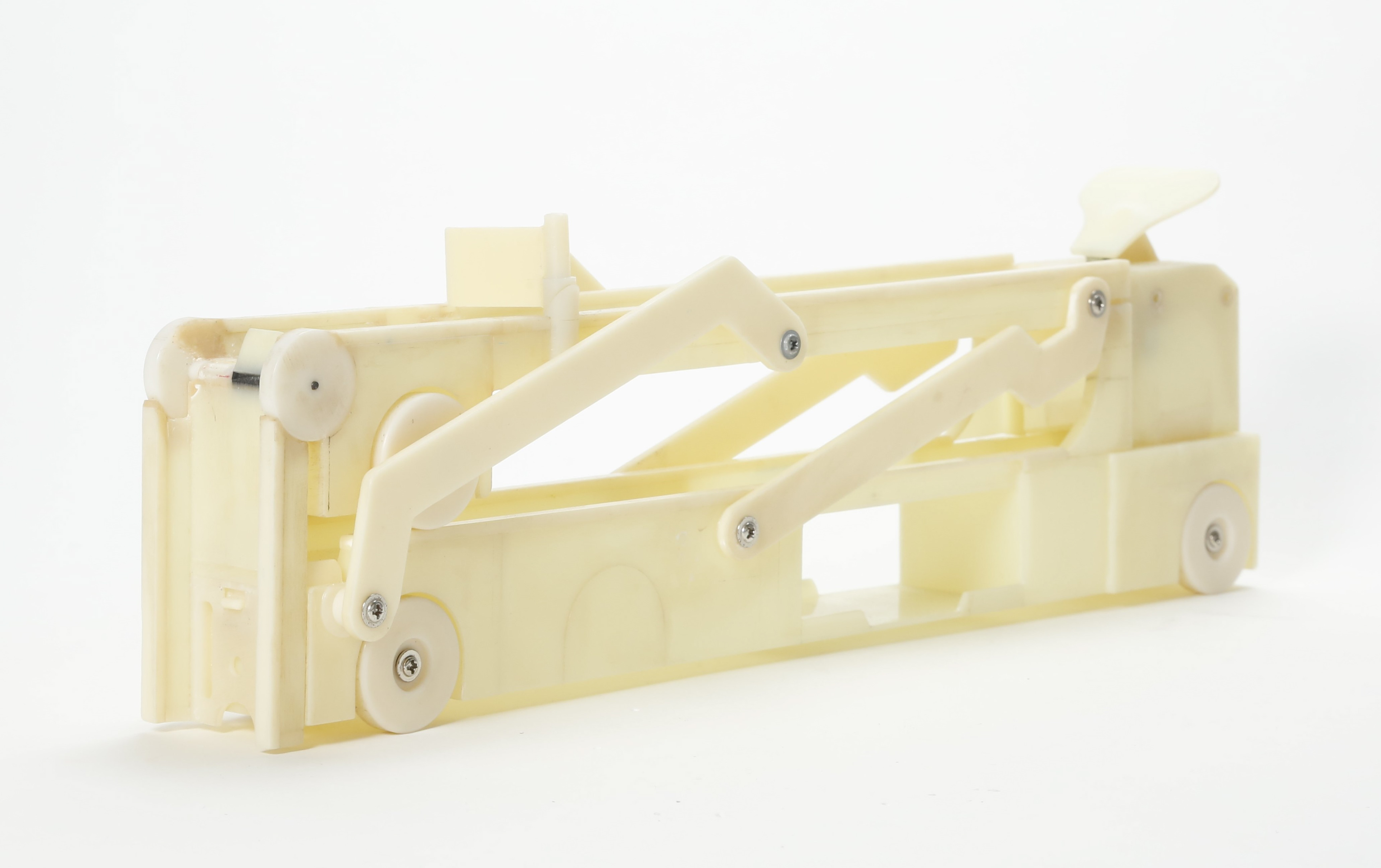

After B-sheets are sent to the production team, a "proof-of-concept" model is created. This model lacks details, and is simply a functioning model that tests the mechanisms and play of the toy. The team sends each model iteration back to the design team to analyze.

Once the toy functions as intended, the production team can move onto a detailed sculpt of what the final toy will look like. They will reference the details shown in the B-sheets provided and will make a painted, hand-made prototype.

The design team will confirm that the sculpt and functionality looks and works as intended. Then tooling can be made for injection molding.

Once tooling is complete, they test it out by creating a toy from it that lacks any color accuracy, and its intention is for inspecting any tooling flaws.

Once sculpt, color, and functionality are all inspected and approved, mass production can begin on the toy, and it is then distributed to the designated buyers.